Perfect Proofer for flexo

The Challenge in creating the right color

Creating the right color is important to meet your customer expectations. Ink management will be -for that reason- an important part in your printing process. For instance, advanced dispensing solutions will support you in making the right color in the right quantity. But also with the help of an ink draw down, with the perfect proofer for flexo.

However, variation in substrates, type of flexo plates, doctor blade condition and change of anilox specifications are parameters that will influence the color outcome from job to job. Thus, predicting the color off press, will reduce your set-up time and waste of substrate and inks.

We have the solution

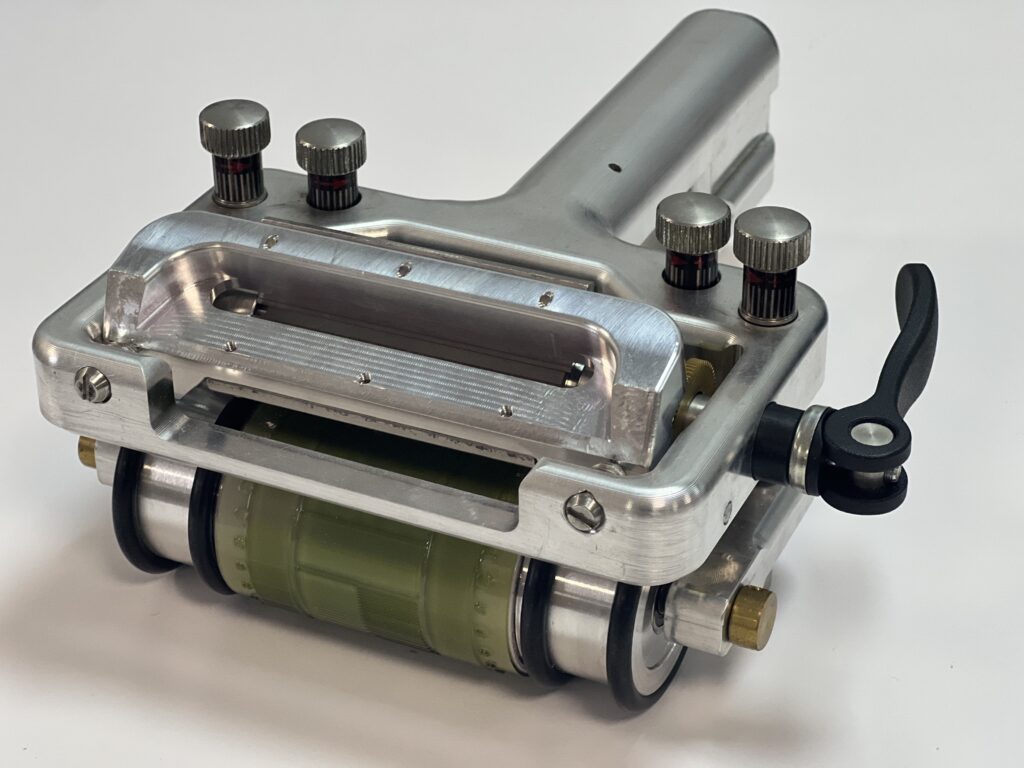

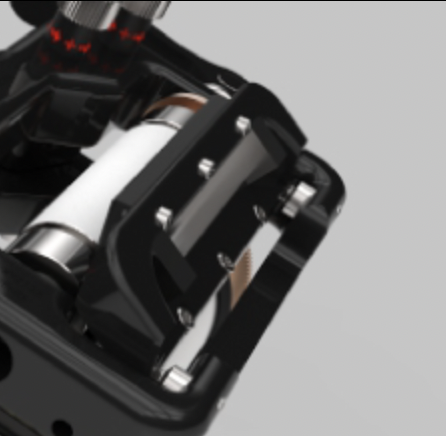

Meet the Evolution Series ES 100, the perfect proofer for flexo. This hand held proofing device utilizes, for example, the same components on your flexographic printing press, including plates, sticky bag and doctor blades. Subsequently, by making a draw down, you will have a truly proof of the ink like on press. Hence, the ES 100 is designed to use all of your 1″ anilox rolls and are easy to exchange.

The ES 100 is easy in use, and also highly effective. This modular build color proof solution can, for example, be adjusted towards your flexo press settings. A simple adjustment of flexo plate and anilox, in similar fashion to your press set-up, will improve the prediction of your color outcome on your press.

Resembles your print press

The ES 100 uses likewise photopolymer plates as you use on your presses. Therefore the used plate material can be processed by yourself. This results in flexibility as well as enables you to customize your plate files, and resolution of plate to your own testing requirements. Furthermore, the patented dot gain technology gives you the ability to measure density and dot gain on your draw down, assuring accurate prediction of the ink performance on press.

Features

- You can use any 1″ anilox

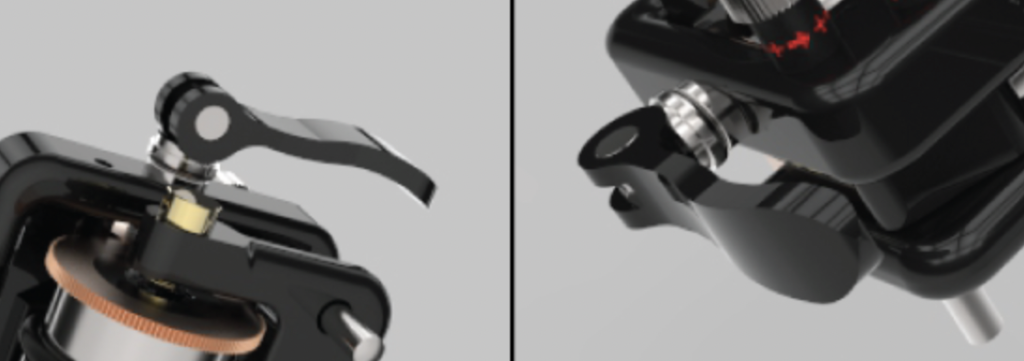

- Snap in dual blade ink metering system

- Toolless quick change anilox

- Designed for any anilox plate and sticky bag thickness

Benefits

- Enables you to mirror anilox on press

- Easy and clean way of doctoring

- Enables using different anilox types

- Enables to mimic flexo plate and sticky bag use on press

Smart Dispensing Solution

SETTING THE STANDARD IN INK LOGISTICS

SELECT THE RIGHT DISPENSING SOLUTION

When you select a smart dispensing solution, it ought to reflect the many variables of your print lay-out. Therefore, we will start the journey to jointly define the scope of needs. Hence, this starts with determining the available space for a dispenser first. Equally important is the ink-type you use, besides the number of base colors.

The GSE Dispensing Solution promise

GSE Dispensing offers solutions that are indeed very accurate in dispensing. Moreover a dispensing solution that helps reducing the environmental impact of inks and ink-related resources. Equally important realizing this ambition through supplying solutions that reduces wastes in ink logistics:

- equipment

- software

- services

It is indeed in GSE Dispensing’s back bone to continuously stand out in the market. That is that the advanced systems with sophisticated software contribute as much as providing you first-class support.

What’s more, a GSE Dispensing Solution has a modular design. Hence an aligned performance of pneumatics, electronics, software, and computer control with the mechanics of fluid flow dynamics.

Robust, fast and smart

Whenever operating a GSE Dispensing solution, you will find this equipment easy to use, to clean, and to maintain. What’s more, the modular architecture of the equipment and software enables smart customization and quick response manufacturing.

Your support provider

Because GSE Dispensing solutions offers equipment that makes a difference, UPrint Technologies is a proud distributor for North and Central America. In order to ensure your GSE Dispensing solution is in optimal condition, our highly skilled service and maintenance team will assure short support lead times. Together with local inventory of essential parts, you are at all times secured of having your dispensing equipment running smoothly.