Anilox Cleaning Strategy

MAKE YOUR PRINTING BETTER

WELL CLEANED ANILOX ROLLERS….. COST SAVINGS THROUGH BETTER PRINTING

Well cleaned anilox rolls or sleeves are determinative in achieving the required color. Therefore, a balanced anilox cleaning strategy will support your print operation efficiency. UPrint Technologies is here to help you: with dedicated cleaners for daily and weekly cleaning, supplemented by periodic deep cleaning on site by our technicians.

A revolution in periodic anilox deep cleaning: the Clean Solutions Group Deepwave

The Deepwave will fit seamlessly into your anilox cleaning strategy. Besides that this revolutionary contactless deep cleaning device will bring your anilox rollers in the best condition, you will achieve quality printing against low operational costs. In order to help you achieve that goal, UPrint Technologies offers a one of a kind anilox rollers cleaning support plan:

- Analyzing the current condition of your anilox rollers;

- Initial treatment of anilox deep cleaning with Clean Solutions Group Deepwave on site;

- For daily and weekly cleaning you follow our tailor developed Green Solutions Group anilox cleaning plan by using our dedicated Clean Solutions Group cleansers;

- Based upon your usage of anilox rollers, we mutual agree upon a once or twice a year anilox deep cleaning with Clean Solutions Group Deepwave by our anilox cleaning service team;

- Analyzing anilox condition and evaluation.

We are here to help you

UPrint Technologies is there for you to support you in keeping your anilox in optimum condition. We will execute this promise by advising you on implementing a smart cleaning concept. Therefore will our concept contribute highly to more efficient quality printing. For instance through reduction of waste of substrate as well as ink consumption, and by achieving the required color faster. An anilox that transfers the right volume of ink, will also contribute to less machine downtime, as you avoid anilox cleaning during the job. Summarized a well-performing anilox will increase efficiency in printing.

Advanced anilox deep cleaning

MAKE YOUR PRINTING BETTER

Advanced anilox cleaning with Deepwave

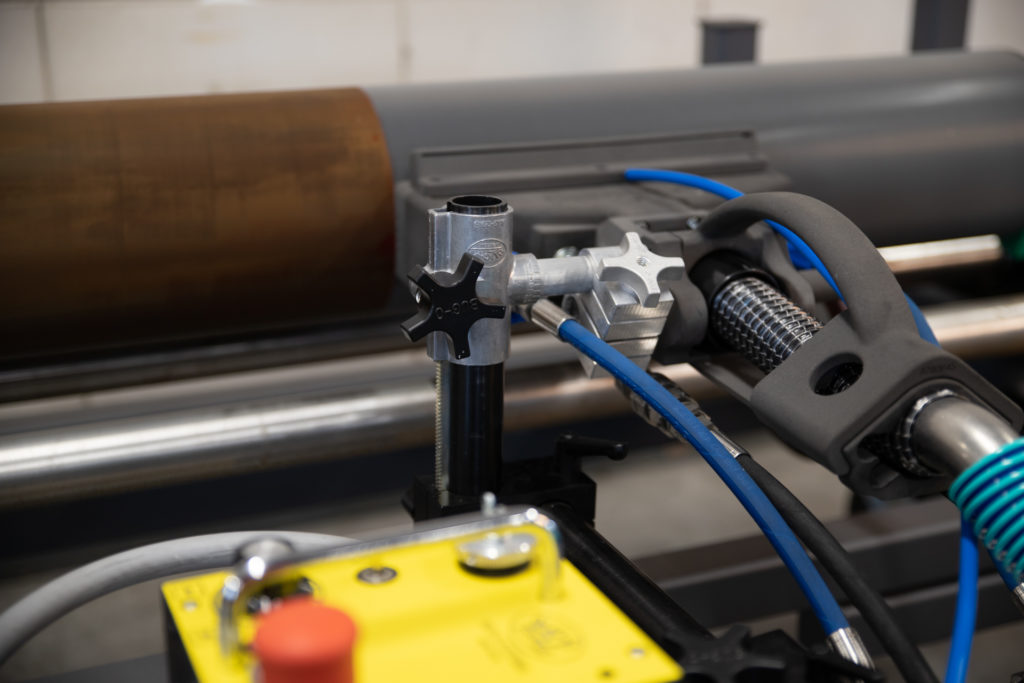

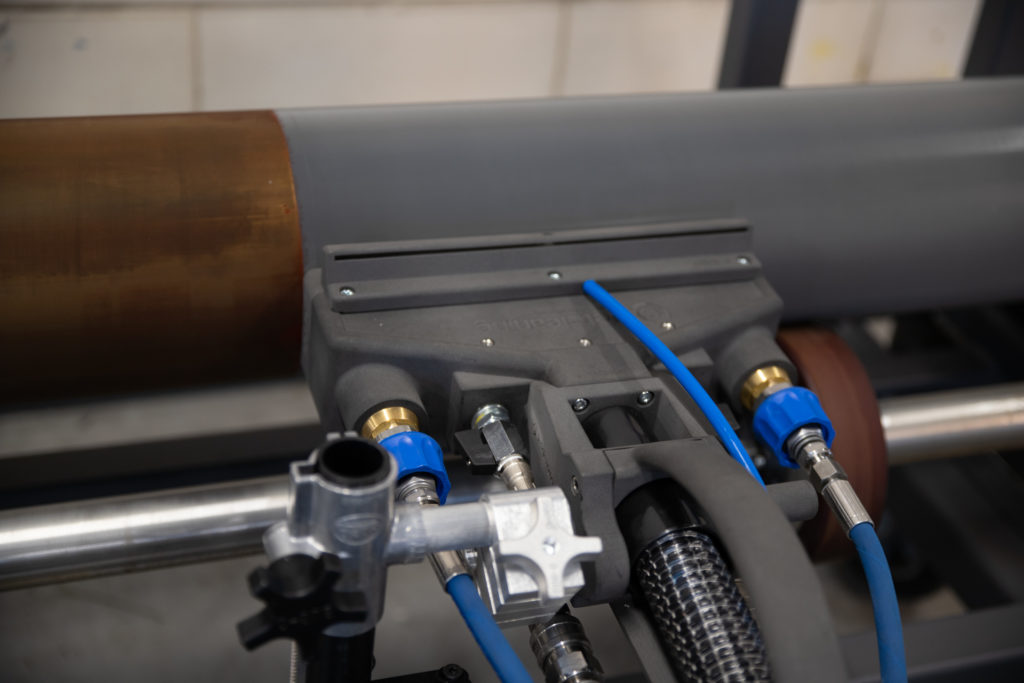

A clean anilox will print better. In fact, with this principle in mind, Clean Solutions Group has engineered a deep cleaning technology. Therefore, meet the next generation of advanced anilox cleaning with Deepwave, a highly efficient and effective anilox deep cleaning device. The Deepwave is not only effective in cleaning, but also maintains the integrity of the cells and dams. As a result, the Deepwave can bring the cell volume back to 95%

When you meet the latest development in anilox deep cleaning: The Deepwave, powered by Clean Solutions Group. The Deepwave is besides fully automated also a non contact anilox cleaning tool. In addition, this concept can achieve a cell volume up to 95%. Therefore, the Deepwave is a game changer in anilox deep cleaning. It also means your printing staff will achieve the color requirements faster.

At the same time, the combined powerful spray and suction head will support you to be in compliance with the strictest company safety policies. Because there is no vaporization of water, cleanser or other material during deep cleaning. Equally important to the cleaning results, this design contributes to realizing a clean and safe pre-press working environment.

This best in class anilox deep cleaning solution can be used both in-line as well as off-line.

Flexoclean Deepwave for anilox cleaning

| Cleaner Volume | 20 liter | Operational Temperature | 25o C |

| Tank Volume | 60 liter | Water Supply | 3/4″ |

| Pressure | 83 Bar | Total weight | 50 kg |

| Suction Unit | 2 x 1200 W | Weight guiding mount | 20 kg |

| Total Output | 4 kW | Minimum Cleaning Height | 70 cm |

| Voltage/Amperage | 380 / 16 V/A | Maximum Cleaning Height | 250 cm |