UPrint Technologies to Showcase Innovative Printing Solution at InfoFlex 2023

Spartanburg, SC, March 12, 2023 – UPrint Technologies, a leading provider of advanced printing solutions, has announced its participation in InfoFlex 2023. InfoFlex has become the premier event for the flexible packaging, corrugated packaging, and label printing industry. The exhibition will take place from April 17-18, 2023, at the Greater Columbus Convention Center in Columbus, OH.

INNOVATIVE PRODUCTS. BETTER PRINTING

At InfoFlex 2023, UPrint Technologies will showcase its latest flexo printing solutions. This includes, Digital Plate Making Equipment, Ink Management Solutions -equipment and software-, Nano Doctor Blades, Anilox Maintenance Strategy Services, as well as Ink Viscosity Monitoring Solutions. The company’s flexo printing solutions are designed to meet the needs of customers in various industries. For example the food and beverage, pharmaceuticals, cosmetics, and more.

“We are excited to participate in InfoFlex 2023 and demonstrate our innovative flexo printing solutions to the industry,” said Edward Scheppink, CEO of UPrint Technologies. “Our flexo printing solutions are designed to help customers improve productivity, reduce waste, and deliver high-quality prints with maximum efficiency.”

State of the Art Digital Flexo Plate Engraving Solutions

With UPrint Technologies’ digital flexo plate engraving solutions the flexo printer can achieve many benefits. One of these benefits is the improved print quality, combined with cost effectiveness. Therefore, UPrint Technologies offers a complete solution of equipment, and work flow. What’s more, UPrint Technologies also offers direct engravable plates, aligned with the flexo plate engraving technology.

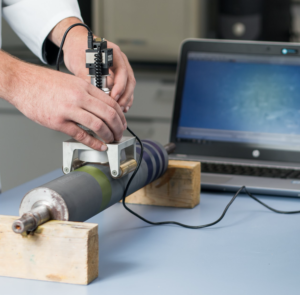

Introduction of Awarded Ink Viscosity Monitoring Systems

Viscosity is the single most crucial ink parameter in flexo printing that has a big impact on print quality output. It is therefore vital to have real-time viscosity data to monitor viscosity properly. Through the next generation of sensors, major improvements of viscosity monitoring have been achieved. Among these improvements are, no re-calibration during the sensor life time, nonsensitive to vibrations from its surrounding, as well as saving previous jobs’ viscosity parameters.

INNOVATIVE SOLUTIONS THAT CONTRIBUTE TO BETTER PRINT QUALITY AND EFFICIENCY

Furthermore, UPrint Technologies will showcase the revolutionary Nano Doctor Blade Technology, Smart Ink Management Solutions, and Anilox Maintenance Strategy Services.

UPrint Technologies’ team of experts will be available at Booth 740. At their booth the exhibition visitor will find all the company’s flexo printing solutions showcased. The show will also allow to discuss how they can help customers achieve their printing goals.

About UPrint Technologies

UPrint Technologies is a leading provider of advanced flexo- and screen printing solutions. Their solutions help customers achieve their printing goals with maximum efficiency. Thus the company’s portfolio of printing solutions includes digital flexo plate engraving solutions, ink management systems, Nano technology doctor blades, rotary screen printing solutions, and non-contact functionality optimization. UPrint Technologies is committed to providing its customers with outstanding quality, service, and support.

For more information, please contact:

Edward Scheppink

UPrint Technologies, LLC

(864) 278 0400

info@uprinttech.com

How does a clean anilox contribute to high quality printing and production efficiency?

Where do you need to attend to when using an anilox

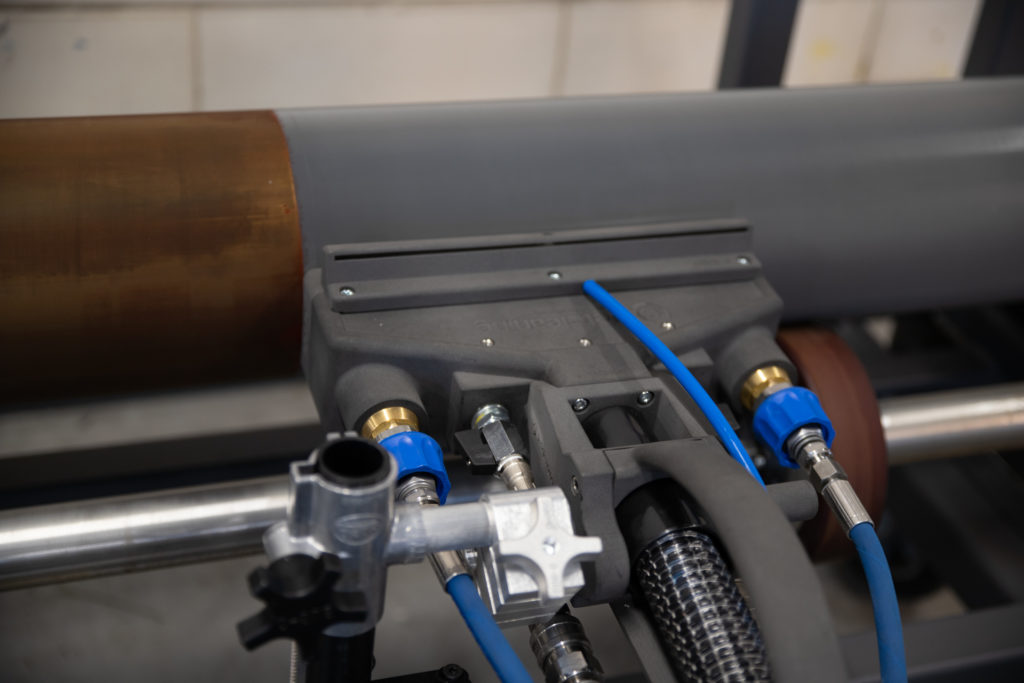

An anilox is a critical component of the flexo printing process. Therefore it is essential to keep them well-maintained to ensure optimal performance and print quality. Here are some important procedures to attend to for an anilox.

- Cleanliness: Regular cleaning is critical to maintaining the anilox’s optimal performance. The cells of the anilox can become clogged with ink or debris. This can lead to inconsistent ink transfer, lower print quality, and potential damage to the roller. Regular cleaning helps to prevent these issues.

- Cell volume: The cell volume of the anilox determines the amount of ink transferred to the printing plate or substrate. It is essential to maintain the cell volume of the anilox to ensure accurate ink transfer and color reproduction. Measuring the cell volume periodically can help you identify when the anilox needs to be replaced or re-engraved.

- Engraving quality: The quality of the anilox’s engraving is crucial to its performance. A well-engraved anilox ensures consistent ink transfer and print quality. Regular inspection of the anilox’s engraving can help identify any potential issues that may affect its performance.

- Storage and Handling: Proper storage and handling of an anilox is important to maintain their performance and extend their useful life. An anilox should be stored in a dry, clean environment, and handled carefully to avoid any damage to the cells or engraving.

In summary, attending to anilox’s cleanliness, cell volume, engraving quality, and storage and handling is critical to ensuring optimal performance and print quality. Regular maintenance and inspection can help identify any potential issues and therefore prevent problems from arising.

What are the benefits or a well cleaned anilox?

Cleaning your anilox regularly and effectively is essential to ensure consistent and high-quality printing. Here are some benefits of a well-cleaned anilox

- Consistent Ink Transfer: A well-cleaned anilox helps to ensure consistent ink transfer. This is necessary for producing high-quality prints. By removing any clogged cell, the ink can be transferred evenly and consistently onto the substrate. Thus resulting in a sharper, more defined image.

- Increased Print Quality: A clean anilox helps to produce higher quality prints by reducing the occurrence of printing defects like pinholes, streaks, and color variations. This is because a clean anilox can deliver the right amount of ink to the printing plate or substrate, leading to accurate color reproduction and sharp images.

- Longer Anilox Life: Regular cleaning of your anilox can also help to extend its lief. By removing any built-up ink or debris, you can prevent damage to the cells of the anilox, reducing the risk of wear and tear and extending its useful life.

- Reduced Downtime: A well-maintained anilox can help to reduce downtime, as there will be fewer instances of ink-related issues that require troubleshooting and cleaning. This means less time spent on maintenance and more time spent on actual printing.

- Cost Savings: By keeping your anilox clean and well-maintained, you can avoid costly repairs or replacements that may be required if the anilox becomes damaged or worn due to neglect. Additionally, consistent print quality can reduce the need for rework and reprints, saving both time and money

In summary, a clean anilox is essential for achieving high print quality, it ensures consistent ink transfer, accurate color reproduction, longer anilox life, reduced downtime, and cost savings.

How will UPrint support you in your anilox cleaning strategy?

Keeping your anilox well-maintained contributes to better print quality and production efficiency. UPrint Technologies offers a program of cleaning agents for the daily, and weekly cleaning of your anilox.

And what is more, our sister organization UPrint Services provides a unique deep anilox cleaning process. With state of the art deep cleaning solution, we bring the cell volume of your valuable anilox to an almost new engraved anilox.

UPrint Services supports this process with anilox status reporting, when received, and after cleaned. We will also provide you with an assessment of window of replacement of the anilox.