ENHANCE THE SILENCE SALES MAN

BECAUSE A LABEL IS MORE THAN JUST AN IDENTIFIER

In the bustling aisles of retail stores, where products vie for attention and consumers make split second decisions, there exists a silent yet powerful force that often goes unnoticed – the humble label. While labels may seem like a mundane aspect of packaging, they play a crucial role as silent salesmen on the shelf, quietly influencing purchasing decisions and driving sales. In this article, we explore the hidden potential of labels as silent salesmen and the strategies brands can employ to harness their power effectively.

The Quiet Influence of Labels

Labels are more than just identifiers – they are miniature advertisements, conveying vital information and communicating brand messages in a matter of seconds. From product names and descriptions to branding elements and nutritional information, labels serve as silent ambassadors for brands, engaging consumers and shaping their perceptions at the point of purchase.

Consider the following scenarios: A shopper perusing the beverage aisle is drawn to a bottle adorned with an elegant label, featuring vibrant colors and enticing imagery. Without uttering a word, the label communicates sophistication, quality, and taste, prompting the shopper to reach for the product and make a purchase. Similarly, a health-conscious consumer scanning the shelves for snacks immediately captivated by a package bearing a label adorned with bold claims of natural ingredients and nutritional benefits. In an instant, the label establishes credibility and trust, compelling the consumer to choose the product over competing options.

Strategies for Maximizing Label Impact

To unleash the full potential of labels as silent salesmen, brands must adopt strategic approaches that enhance visibility, convey value, and resonate with target audiences. Here are some key strategies to consider:

- Eye-Catching Design

- Clear Messaging

- Brand Story Telling

- Differentiation

- Interactive Elements

The Future of Labeling

As technology advances and consumer preferences evolve, the role of labels as silent salesmen will continue to evolve. From smart labels that provide real-time product information to personalized labels that cater to individual preferences, the future holds endless possibilities for innovation in labeling technology.

Precision at its Finest : Why choosing direct laser engraving of flexo plates?

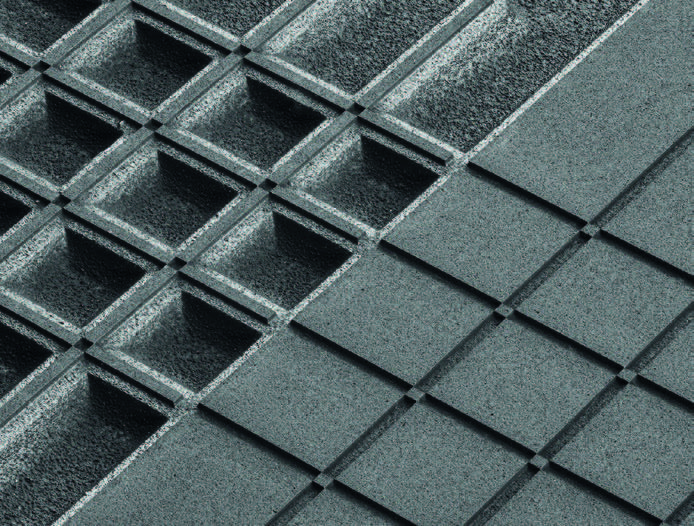

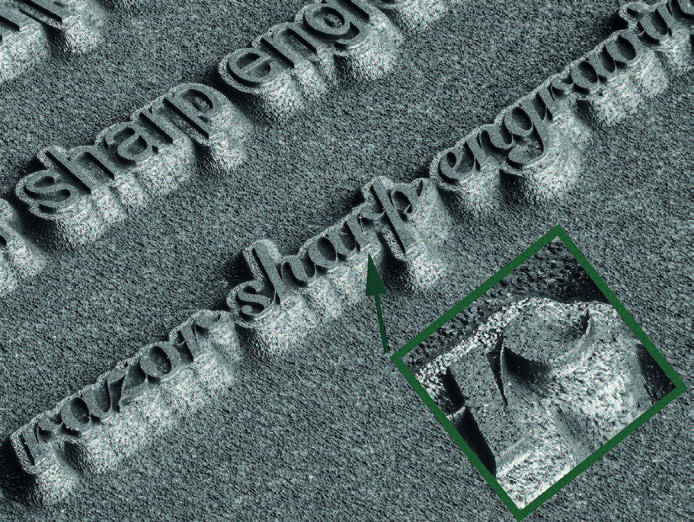

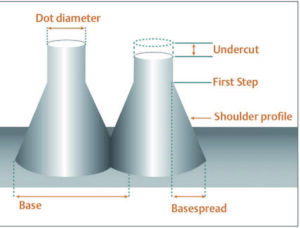

Direct laser engraving of flexo plates offers unparalleled precision and detail, allowing label printers to achieve razor-sharp images, intricate patterns, and fine text that captivate the senses. Unlike traditional plate making methods, which rely on mechanical or chemical processes, laser engraving utilizes advanced laser technology to directly etch the image onto the plate surface with exceptional accuracy and consistency.

Vibrant Color Reproduction

One of the key advantages of direct laser engraving is its ability to reproduce vibrant colors and intricate designs with unmatched fidelity. By precisely controlling the depth and shape of the engraved dots, laser engraved flexo plates ensure optimal ink transfer and color saturation, resulting in labels that pop with vivid hues and rich textures. Whether it’s bold graphics, intricate patterns, or photorealistic images, direct laser engraving enables printers to unleash their creativity and bring their designs to life with breathtaking clarity and brillance.

Enhanced Efficiency and Productivity

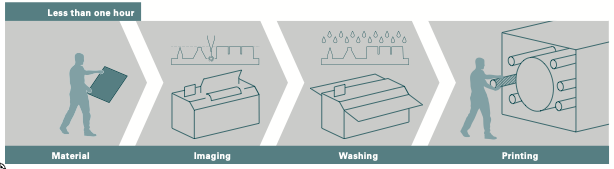

In addition to superior print quality, direct laser engraving offers significant advantages in terms of efficiency and productivity. Unlike traditional plate-making processes, which can be time consuming and labor intense, laser engraving is a highly automated and streamlined process that minimizes setup time and reduces the risk of errors. With faster turnaround times and fewer production bottlenecks, label printers can meet tight deadlines and handle high-volume jobs with ease, ensuring seamless workflow and optimal productivity.

Versatile Direct Laser Engraver for Printing Plates

The HELL PremiumSetter D1000 is an innovative engraving system for direct laser engraving of elastomer plates (polyester or metal substrates) for dry offset, letterpress, flexographic printing, and coating plates and for imaging digital photopolymer printing plates (LAMS).

Using up to two fiber lasers (600 W) with a total output of 1200 W, the D1000 takes the existing performance in this market segment to a whole new level. An integrated loading table incorporating stops, a vacuum cylinder with clamping bar, and footswitch control results in extremely user-friendly plate loading and unloading.

The D1000 works with a resolution of up to 5080 dpi and can engrave plates in a maximum format size of 53″ x 42″.

Features

Fiber Laser

Choose either 1 beam (600 W) or 2 beams (1,200 W)

Digital 3D design of printing elements

Simplified Plate Handling

| Printing Plates | Premium Setter D 1000 |

| Plate Types | – Elastomer on steel-base plates – Elastomer on polyester-base plates – Digital photopolymer plates (LAMS) |

| Plate Thickness | up to 0.25″ |

| Plates Size | Sizes up to 53″ x 42″ Can be imaged up to max. 51″ x 41″ |

Applications

Dry Offset for Metal Decoration printing

Label Printing

Pre-press essentials for screens

THERE IS A WAY TO DO IT BETTER

A market leader in pre-press essentials for screens

Five decades of dedication to the screen printing technology, as an illustration, features this family owned company at its best. At the same time, AMEX Manoukian is dynamic and also customer requirements focused. This is realized, for instance, through the passion for improving the efficiency and quality of the screen printing technology. Therefore, today AMEX has grown into a market leader position in the pre-press essentials for rotary screen market.

Engaged with customers

Consequently, the market demand engaged customer team of AMEX deploys its decades of experience to find new solutions. But also to keep pace with rapid changing environmental and what’s more the quality requirements. Therefore, this approach will provide innovative products for better printing performance. And so, AMEX offers a complete program of pre-press essentials for making and reclaiming rotary textile as well as label screens.

And developing innovative products

Surely, the core of all AMEX innovation is their sophisticated aboratory. AMEX uses, to illustrate, advanced development technology and high quality raw materials. At the same time, AMEX is respectful for the environment. That is to say, AMEX has developed a portfolio of innovative products. Each solution contributes to improved printing as well as profitability.

As a result highly efficient Pre-press essentials

To conclude, UPrint Technologies offers a complete rotary screen processing portfolio. As a result of the unique formulation of the pre-press essentials, you will achieve high efficiency. But also better printing quality. The next generation photo-emulsion, for example, requires less layers and provides better resistance against ink and as well crisp and sharp details of the printed matter. This solution, for that matter, can save up to 40% in material usage, but also in labor.

Find you application

| Product Name | Application |

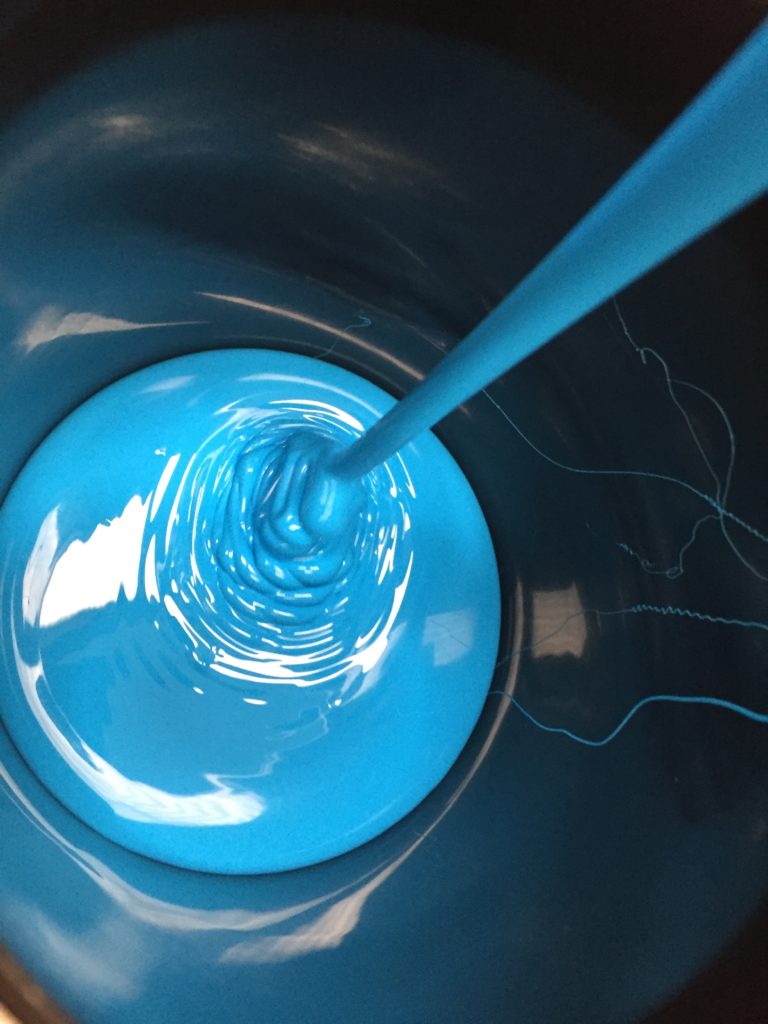

| AMEX SCREEN SOL ROTO BLU | Photo-emulsion for the purpose of film, wax, inkjet laser technology |

| AMEX SCREEN SOL ROTO BLU PLUS | Photo-emulsion for the purpose of film, wax, inkjet laser, CTS technology |

| Product Name | Application |

| AMEX SCREEN SOL QS VIOLA | Photo-emulsion for laser exposing (CTS), laser engraving (Co2) technology as well as UV-exposing with film |

| AMEX SCREEN SOL ROTO LASER | Photo-emulsion for the purpose of laser engraving (CTS) technology |

| AMEX SCREEN-CHEM FILLER | One component retouching laquer for the purpose of filling small pin holes |

| AMEX SCREEN-CHEM STRIP | Photo-emulsion remover for the purpose of screen reclaiming |

| AMEX SCREEN-CHEM GHOST | One component ghost image remover for the purpose of screen reclaiming |

| AMEX SCREEN-CHEM DEGREASER | Eco-friendly concentrated degreaser for the purpose to clean the screen before adding the photo-emulsion |

| AMEX SCREEN-CHEM BOND AR | Two components adhesive for the purpose of mounting aluminum end rings |