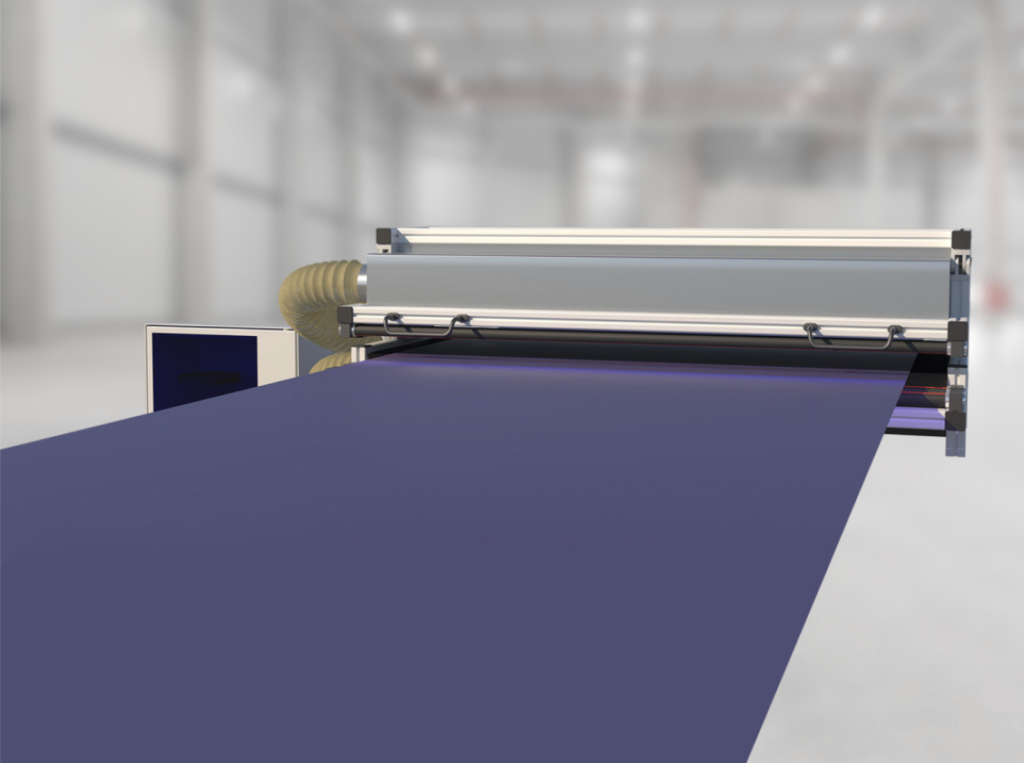

Coating and Wall Cover Printing

NEW ERA OF COATING AND WALL COVER PRINTING

SCREENS FOR COATING AND WALL COVER PRINTING

When your customer is expecting high quality printing results of coating or wall covering, UPrint Technologies is the right partner to help you find the best screen solution for the job. Our unique state of the art technology enables the screens to reach high open area with sufficient hole size, while keeping high mesh and extra thickness.

Thanks to its high open area and adequate hole size, our wall covering screens enable higher embossing effect while keeping sharp edges for PVC or water based foam ink.

Talk with us to find the right screen for your application

Find the right screen for the required end result:

| LR-series | Light coating and pattern printing |

| SP-series | Paste coating of pattern or design |

| CH-series | Medium heavy coating of foam |

| HX-series | Extra heavy coating of (PVC) foam |

Specification Sheet Wall Covering Printing

| Mesh | Thickness (um) | Open Area (%) | Hole Size (um) |

| 25 | 150 | 50 | 720 |

| 30 | 120 | 60 | 655 |

| 40 | 120 | 50 | 550 |

| 40 | 150 | 38 | 450 |

| 70 | 120 | 35 | 250 |

| 80 | 150 | 25 | 160 |

| 80+ | 150 | 38 | 201 |

| 100 | 150 | 20 | 115 |

| 100+ | 150 | 38 | 162 |

| 125 | 150 | 20 | 94 |

| 130 | 120 | 33 | 111 |

| 160 | 120 | 27 | 80 |

| 190 | 120 | 24 | 64 |

| Mesh | Thickness (um) | Open Area (%) | Hole Size (um) |

| 40 | 125 | 20 | 300 |

| 60 | 125 | 14.5 | 165 |

| 70 | 125 | 12.5 | 130 |

| 125 | 120 | 12.5 | 130 |

| 125+ | 110 | 23 | 102 |

| Mesh | Thickness (um) | Open Area (%) | Hole Size (um) |

| 40 | 200 | 22 | 300 |

| 40+ | 200 | 40 | 400 |

| 50 | 165 | 41 | 325 |

| 50 | 200 | 12 | 175 |

| 80 | 200 | 25 | 160 |

| Mesh | Thickness (um) | Open Area (%) | Hole Size (um) |

| 25 | 300 | 30 | 555 |

| 30 | 300 | 40 | 536 |

| 40 | 210 | 25 | 320 |

| 40 | 300 | 30 | 350 |

| 40 | 350 | 12 | 220 |

| 40 | 400 | 20 | 285 |

Repeat in mm (inch) : 640 (25″) – 914 (36″)

Length in mm : 1,450 – 1,780 – 1,980 – 2,000

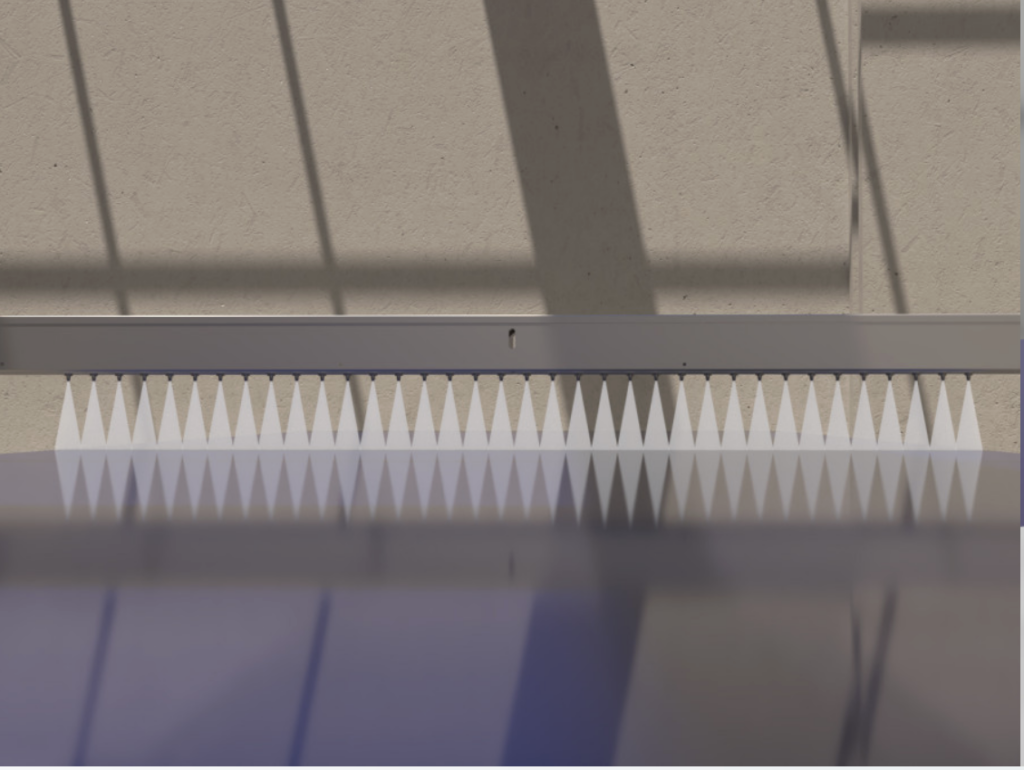

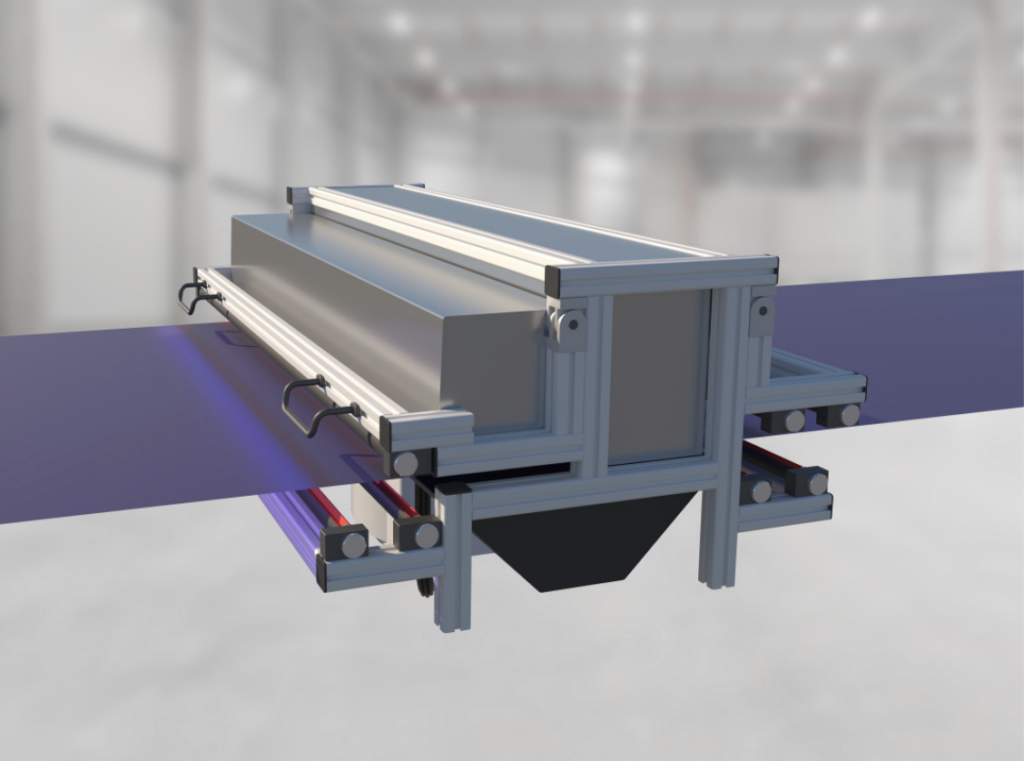

Weko ESC

ESPECIALLY UNIFORM PRECISE POWDER SPRAYING

The WEKO Powder Application system is engineered especially for the high requirements on advanced machines in the gravure and flexo printing, plastic film production and specialty applications. Specifically when a very uniform and precise layer of powder is needed and high production speeds are the norm.

The principle explained in brief

The WEKO ESC is a modular system, which consists of a powder application and an electrostatic unit. First, the web is guided through an ionizing unit. This is needed for the purpose to allow uniform spraying, regardless of the climate or electrical charges. Thereafter follows powder spraying inside the encapsulated spraying chamber. A powder extraction system keeps the air clean. When the web exits the equipment, it is once more discharged through ionizing rods.

A reliable and flexible powder application solution

An advanced powder metering system ensures the uniform precise powder spraying. For instance, even tiny quantity changes can be sprayed exactly and repeatable. What’s more, format setting and adjustment of the powder quantity to the speed or the width of the web is done semi-automatically. Additionally, the type of powder can be quickly changed through the Variobox. The WEKO ESC is available for different powder volumes and to a maximum of 4 meters web width.

Your Benefits

- defined application quantity with large dynamic range, reproducible at any time

- uniform powder application due to ionization system

- choice of three models (4 m maximum width, up to 48 nozzles)

- Variobox® mainly as standard

- integrated powder extraction system (PAS)

- PMS metering system with pre-select function

- hardly any cleaning effort due to minimal powder dusting

- semi-automatic format and speed adjustment

- powder consumption greatly reduced

- easy to operate and maintain

- long service life