How can you by choosing the right doctor blade increase print quality and profitability combined?

The doctor blade is a small but central part of the printing process

A doctor blade is a small but central part of the printing process. As such, it controls the thickness and consistency of the applied ink.

In printing, the doctor blade is used to remove excess ink from the surface of the anilox. This way it leaves only the ink required for printing behind. This ensures that the ink is applied evenly and accurately. This in its turn helps to produce high quality prints.

The doctor blade can be made of a variety of materials, including metal, plastic, and rubber. The choice of material depends on the application and the properties of the material being applied.

How can the right doctor blade contribute to increased print quality and profitability combined?

Using a bad or worn-out doctor blade can lead to various problems in printing. Some of the common problems that tell you to change your doctor blade are:

- Inconsistent printing: A bad doctor blade can cause uneven application of the ink, resulting in inconsistent print quality. This can lead to quality issues and can effect the overall appearance and performance of the final print.

- Excessive material waste: A bad doctor blade may not be able to properly remove excess ink, and thus leading to wastage of material and increased production costs.

- Reduced printing speed: A worn-out doctor blade may not be able to remove the ink quickly enough, and therefore leading to slower production speeds and longer production times.

- Damage to the anilox: A bad doctor blade can cause scratches or other damage to the anilox, which can lead to poor print quality or the need for costly repair or replacements.

- Increased maintenance and downtime: Using a bad doctor blade can increase the frequency of maintenance and downtime required for the printing equipment. As such a the bad doctor blade may therefore need to replaced more frequently or may cause equipment issues.

How can we meet increasing demands on productivity and sustainability combined with increasing profitability?

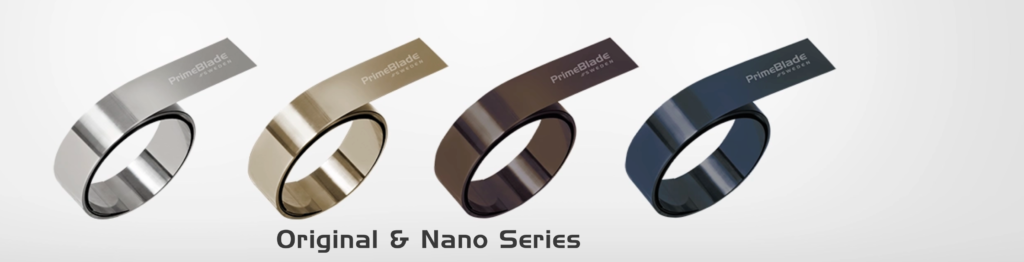

We are confident that this is possible if we focus on all the parts in the chain. The high quality Swedish steel, used in PrimeBlade doctor blades for instance, is made from recycled steel. And what’s more, it can be further recycled into new products after end-of-life as a doctor blade.

The packaging industry is facing a transformation, where all parties involved need to participate actively. Therefore, solutions, concepts, and products need to be designed in such a way that they may interact seamlessly with others up or down the value chain.

PrimeBlade doctor blades are designed to create a worry-free production environment, to ensure consistency in printing, avoid excessive material waste, and damage to the anilox. Only this way, you will achieve high quality printing, with increased profitability.