Non-contact functionality optimization

Weko ESC

ESPECIALLY UNIFORM PRECISE POWDER SPRAYING

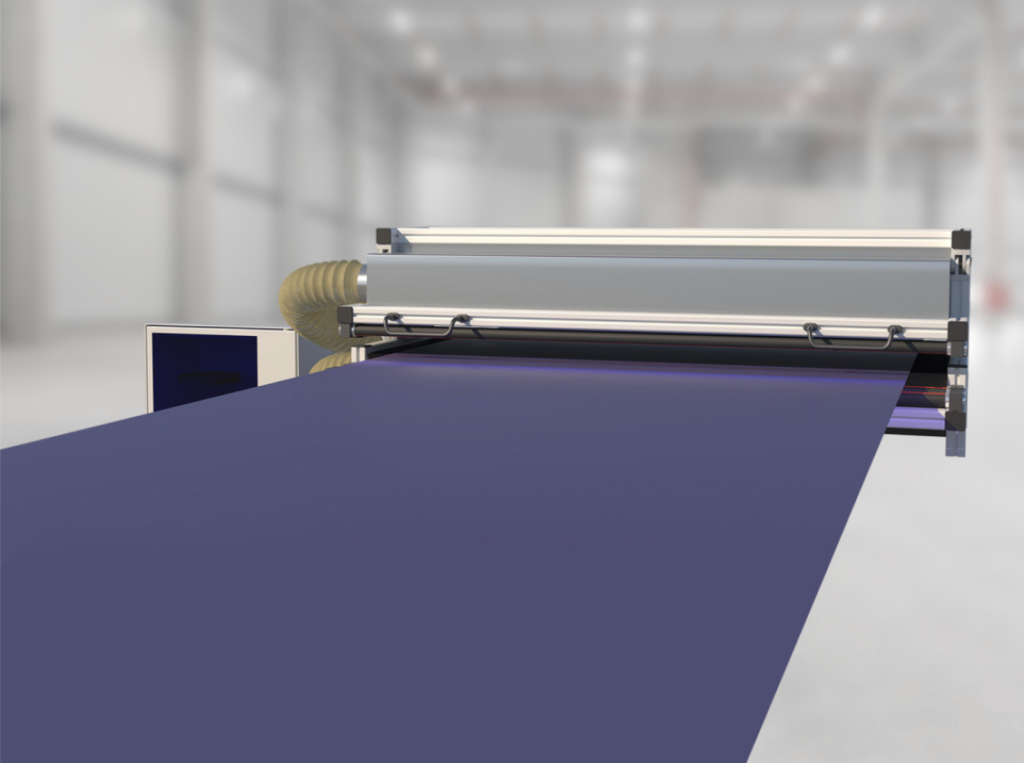

The WEKO Powder Application system is engineered especially for the high requirements on advanced machines in the gravure and flexo printing, plastic film production and specialty applications. Specifically when a very uniform and precise layer of powder is needed and high production speeds are the norm.

The principle explained in brief

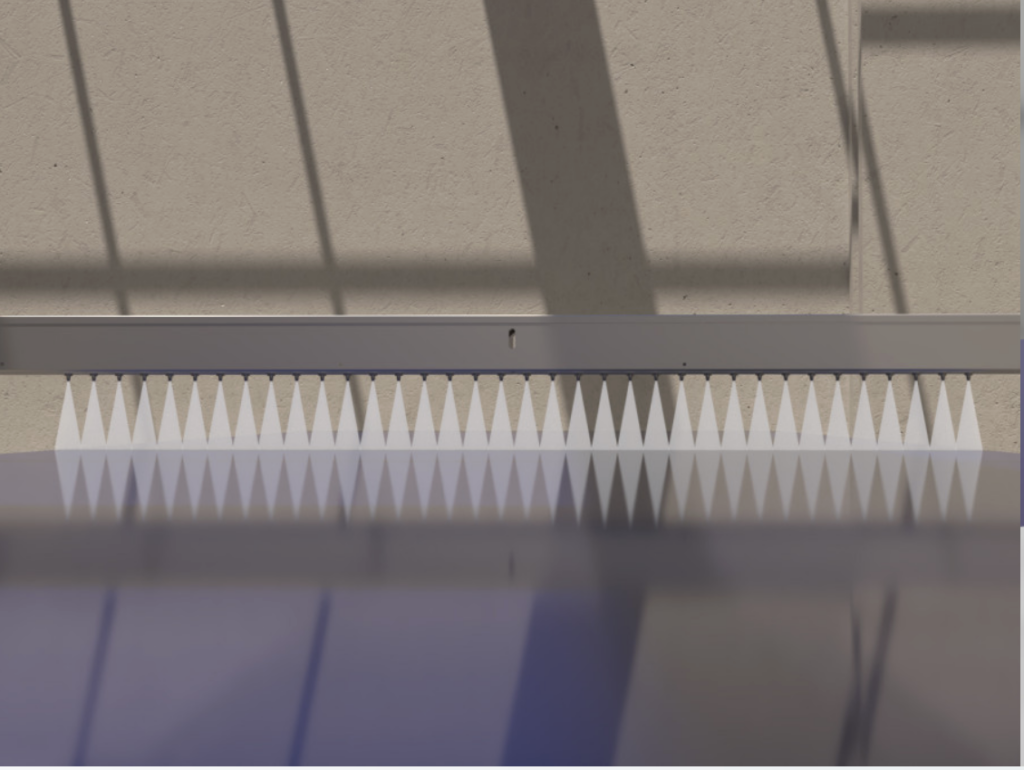

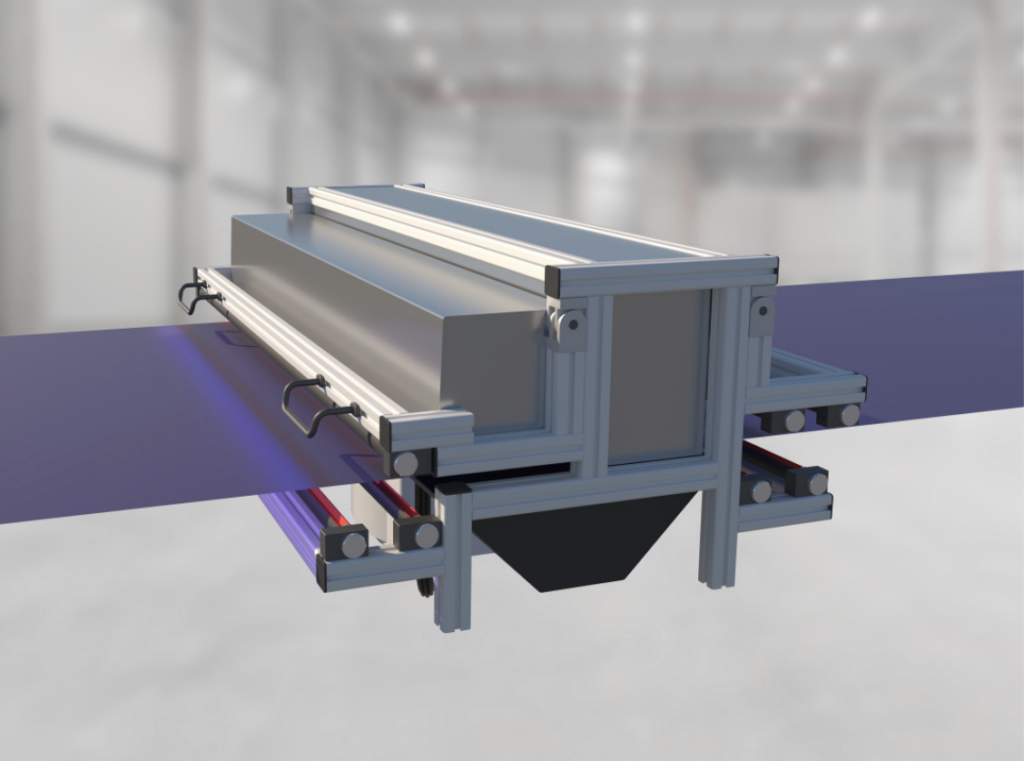

The WEKO ESC is a modular system, which consists of a powder application and an electrostatic unit. First, the web is guided through an ionizing unit. This is needed for the purpose to allow uniform spraying, regardless of the climate or electrical charges. Thereafter follows powder spraying inside the encapsulated spraying chamber. A powder extraction system keeps the air clean. When the web exits the equipment, it is once more discharged through ionizing rods.

A reliable and flexible powder application solution

An advanced powder metering system ensures the uniform precise powder spraying. For instance, even tiny quantity changes can be sprayed exactly and repeatable. What’s more, format setting and adjustment of the powder quantity to the speed or the width of the web is done semi-automatically. Additionally, the type of powder can be quickly changed through the Variobox. The WEKO ESC is available for different powder volumes and to a maximum of 4 meters web width.

Your Benefits

- defined application quantity with large dynamic range, reproducible at any time

- uniform powder application due to ionization system

- choice of three models (4 m maximum width, up to 48 nozzles)

- Variobox® mainly as standard

- integrated powder extraction system (PAS)

- PMS metering system with pre-select function

- hardly any cleaning effort due to minimal powder dusting

- semi-automatic format and speed adjustment

- powder consumption greatly reduced

- easy to operate and maintain

- long service life