SUSTAINABLE CLEANING. UNMATCHED CONTROL

BECAUSE EFFICIENCY IS DOING BETTER WHAT IS ALREADY BEING DONE

Major forces have been squeezing the printing industry in recent years. Macroeconomics, the shift to digital, and the demand reduction. A small work pool from where to hire and an aging workforce. Environmental agencies and consciousness brands enforcing the need for more sustainable printing processes are just some of those pressures.

With that as a background, it is not every day that one new piece of equipment can help address one of those issues, much rather all at once.

COULD SOMETHING BE IMPROVED ABOUT PLATE CLEANING?

We are convinced that a plate cleaning solution that uses the least water and detergent contributes to the sustainability goals of the corrugated industry. In addition, the control and data on water and detergent consumption are collected, supporting the corrugated printing industry in submitting reliable sustainability reports.

Furthermore, finding qualified staff for plate cleaning is getting complicated, and the labor-saving potential is also important. Skilled staff can be assigned other operational tasks that contribute to create (higher) added value. We estimate that MultiClick™ provides labor-saving of 1 FTE/year. Allowing for a very fast ROI.

Soft savings are also found in the absence of plate damage caused by unprofessional cleaning and improved gross

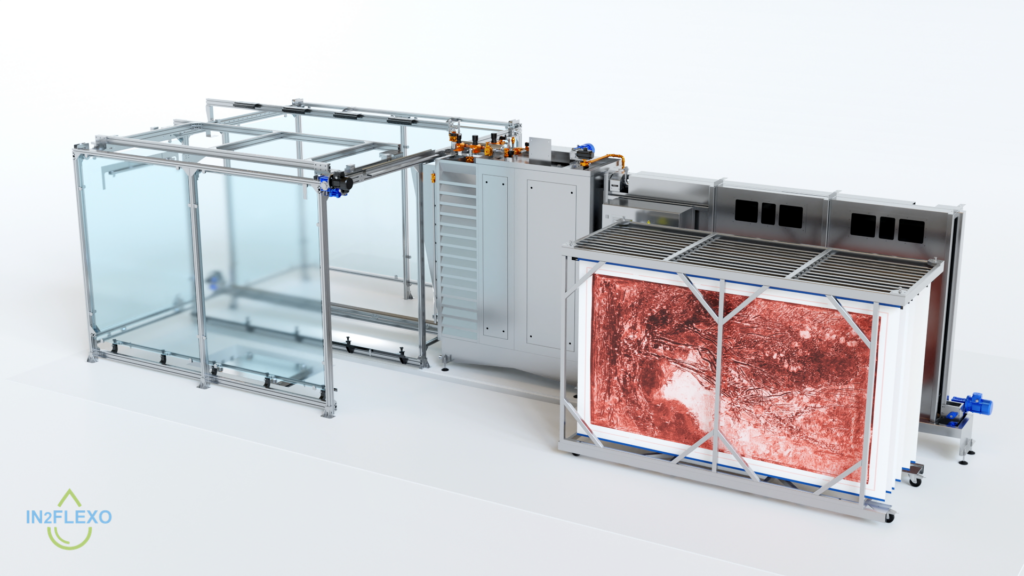

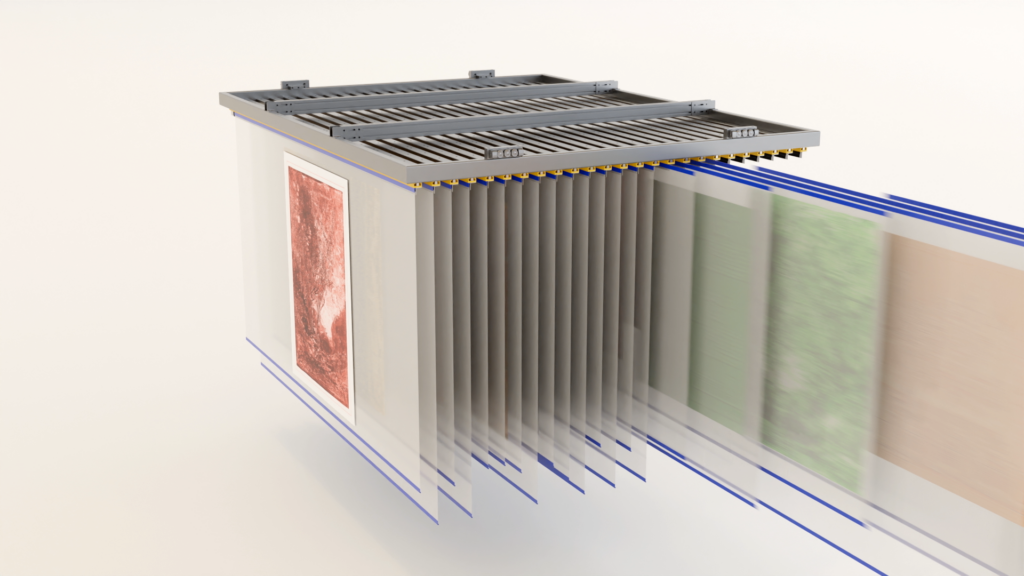

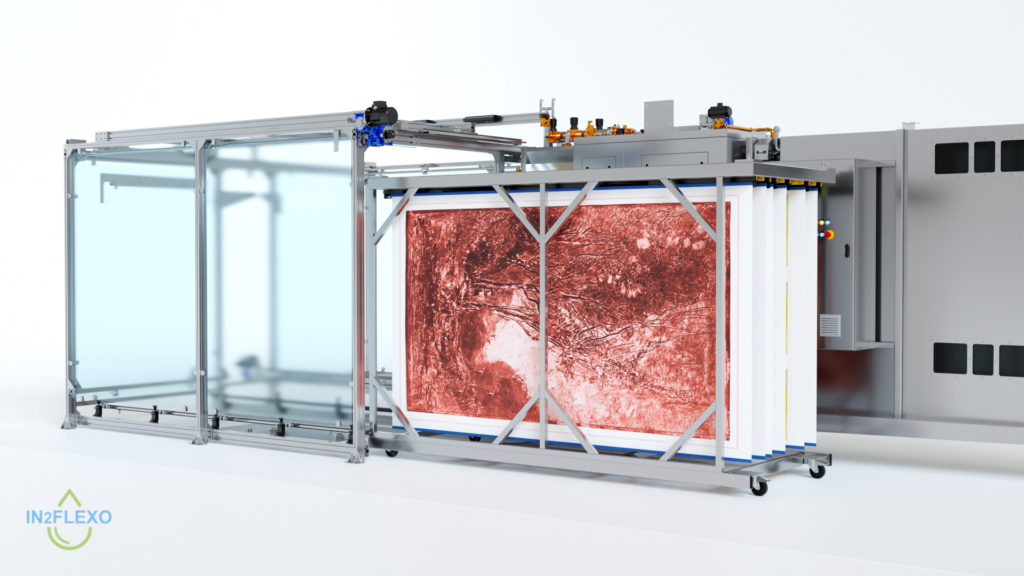

MEET THE MULTICLICK™

MultiClick™ is a Flexo Plate Cleaning System designed for the corrugated printing industry. This state-of-the-art system cleans up to 30 large format flexo plates, reducing water and detergent use, enhancing operational costs, improving sustainability scores, and increasing profits. MultiClick™ provides unparalleled efficiency, minimal operator intervention, and compliance with the latest industrial standards. MultiClick™ is a game-changer in an industry fighting macroeconomic forces, the shift to digital, demand reduction, and an aging and shrinking workforce.

MULTICLICK™ PLATE CLEANING SYSTEM: PROVIDES EFFICIENCY IN PLATE CLEANING

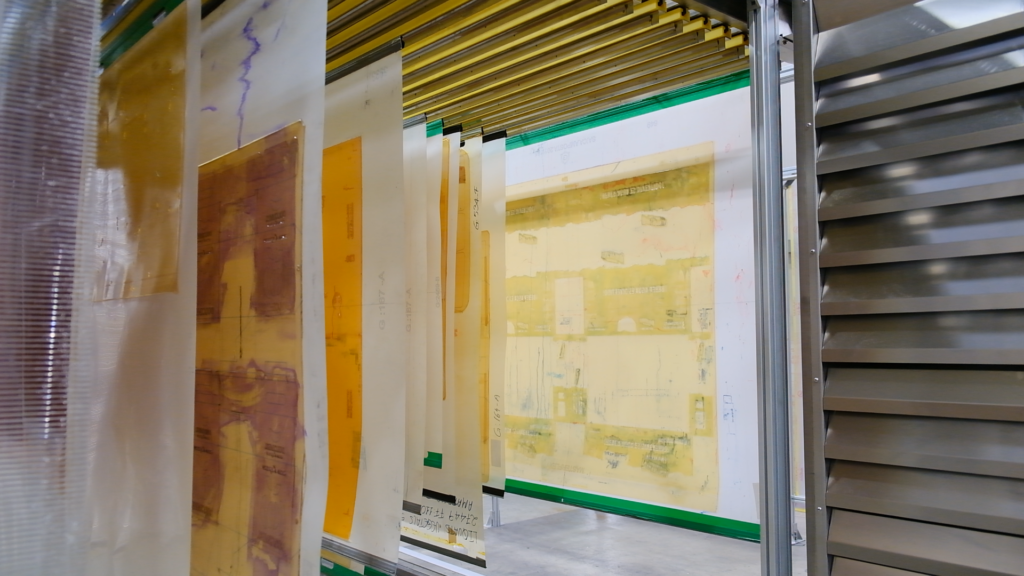

The MultiClick™ is an automatic flexo plate cleaner for the corrugated printing industry. It enables up to 30 large format flexo plates (110” x 65”) to be cleaned in the desired order without operator intervention. Safely producing an optimal, repeatable, and sustainable cleaning result that is fully controllable. MultiClick™ reduces detergent and water consumption, maximizing the plates’ life cycle, eliminating costly human error, and increasing cleaning efficiency, on average, with two minutes per plate.

MULTICLICK™ PLATE CLEANING SYSTEM: CONTRIBUTION TO SUSTAINABILITY

With minimal water and detergent consumption, MultiClick™ improves sustainability scores by allowing full control of dilution parameters and the number of times to re-use detergent. Manufactured in stainless steel, with high-quality electrical components and a user-friendly software interface, MultiClick™ allows for easily adjusting consumption parameters to fit the customer’s needs. It allows to adapt to ink types, such as quick-drying inks and two-component inks, to name a few.

Designed to 4IR (the fourth industrial revolution) standards, MultiClick™ software constantly monitors the cleaning process and collects water and detergent consumption data, enabling reliable sustainability reporting for management and authorities.

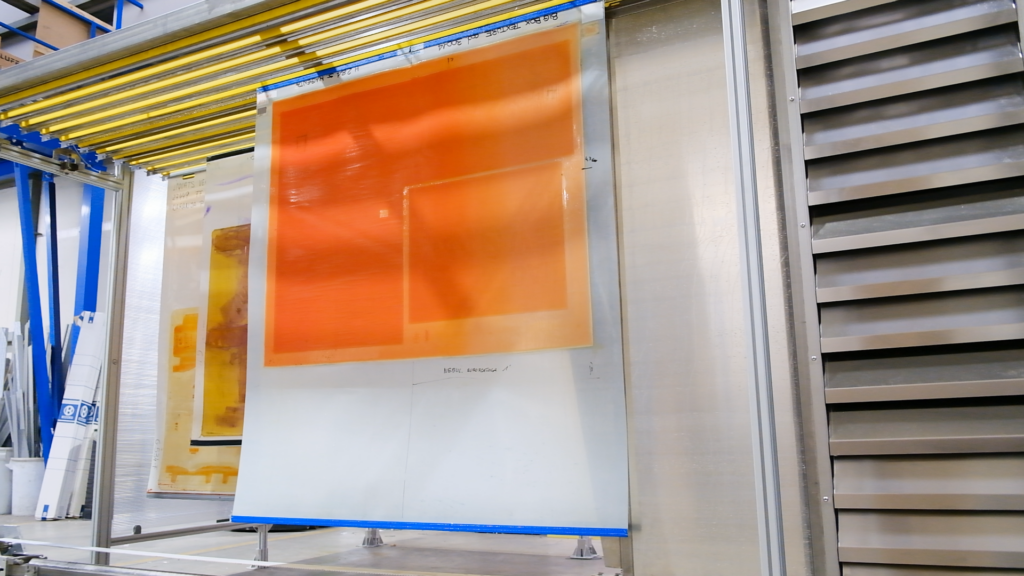

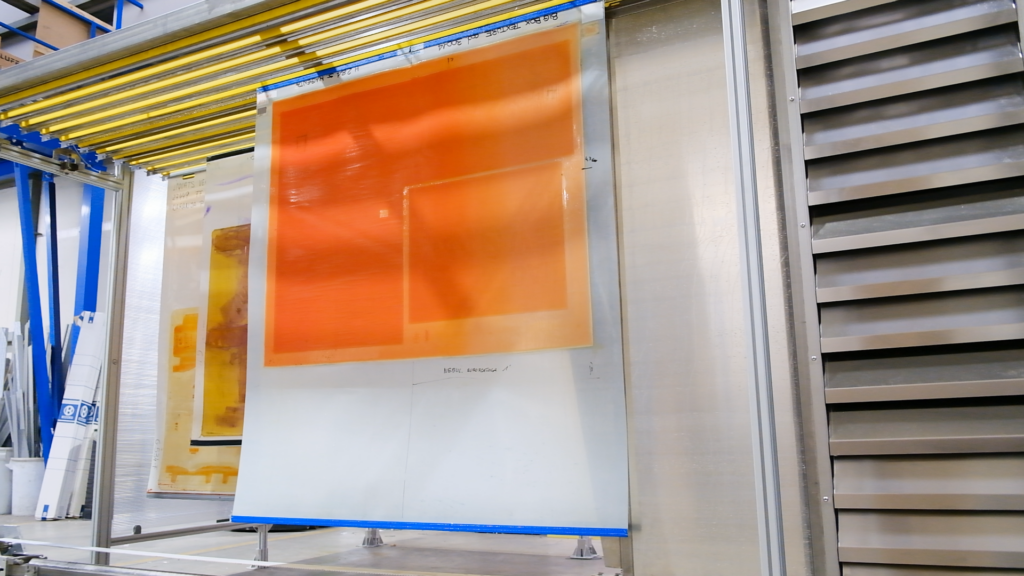

MULTICLICK™ PLATE CLEANING SYSTEM: CONSISTENCY IN PLATE CLEANING

The plate cleaning quality stands out, as the printing plates come out completely clean and dry, ready to be stored or re-used. Reducing downtime due to printing plates’ poor condition after improper cleaning and drying processes.

MultiClick™ safe cleaning process reduces hidden operational costs, such as early plate damage due to inconsistent cleaning.

MultiClick™ revolutionizes the flexo plate cleaning process by adding efficiency, control, scalability, and operation simplicity to a process that otherwise is manual, slow, and extremely dependent on the operator’s skill and work ethic. MultiClick™ is the eco-conscious solution for flexo printers looking to increase margins, reduce their water and consumables bill, increase their sustainability scores, and offer a healthier work environment all in one machine.

With MultiClick™, long gone were the days of cleaning individual plates manually with slow and inconsistent results. MultiClick™ automatic cleaning process delivers flexo plates that are completely clean, dry, and ready for storage or re-use, with cleaning results that are reliable, repeatable, and of the utmost quality level.

THE MULTICLICK™ IS FIT FOR THE FUTURE

Supply Chain Sustainability Objectives are getting tighter.

- Water-saving programs

- Reduction of wastewater

Out of the box, MultiClick™ complies with some of the strictest environmental requirements.

- Controlling and reducing water consumption.

- Controlling and reducing cleaning agent consumption.

- MultiClick™ detergent is ISEGA certified.

Your Benefits are clear

Savings

Automatic loading, unloading and cleaning of up to 30 clichés with an average saving of 2 minutes per cliché.

Quality

Clichés come out completely clean and dry, ready to store and ready for the next run.

Efficiency

Lower consumption, as it offers cleaning/drying with minimum water and detergent consumption (recirculation).

Easy Operation

With a touchscreen where you can select the clichés to be cleaned, the speed and the detergent and water consumption.

Maintenance

It minimizes the risk of cliché breakage. It also avoids cliché deterioration by keeping the clichés clean and dry.

Warranty and Financing

It offers a 12 month warranty and the possibility to finance the equipment for 2 to 5 years.

Equipment Engineered for the High Quality Corrugated Printer

Perfect Proofer for flexo

The Challenge in creating the right color

Creating the right color is important to meet your customer expectations. Ink management will be -for that reason- an important part in your printing process. For instance, advanced dispensing solutions will support you in making the right color in the right quantity. But also with the help of an ink draw down, with the perfect proofer for flexo.

However, variation in substrates, type of flexo plates, doctor blade condition and change of anilox specifications are parameters that will influence the color outcome from job to job. Thus, predicting the color off press, will reduce your set-up time and waste of substrate and inks.

We have the solution

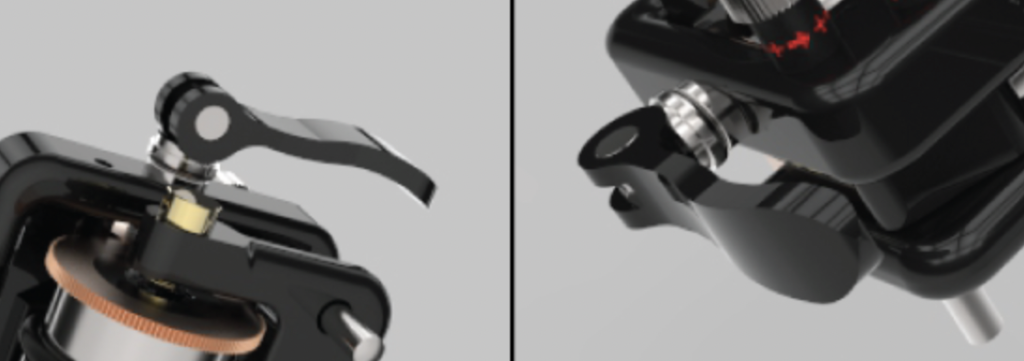

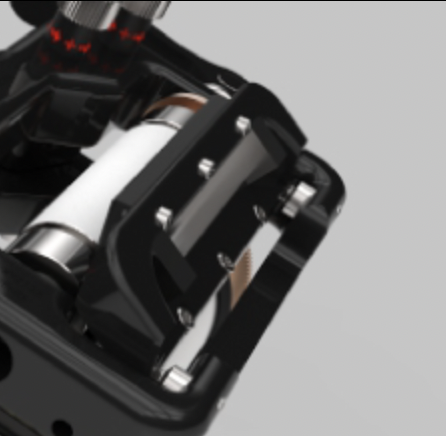

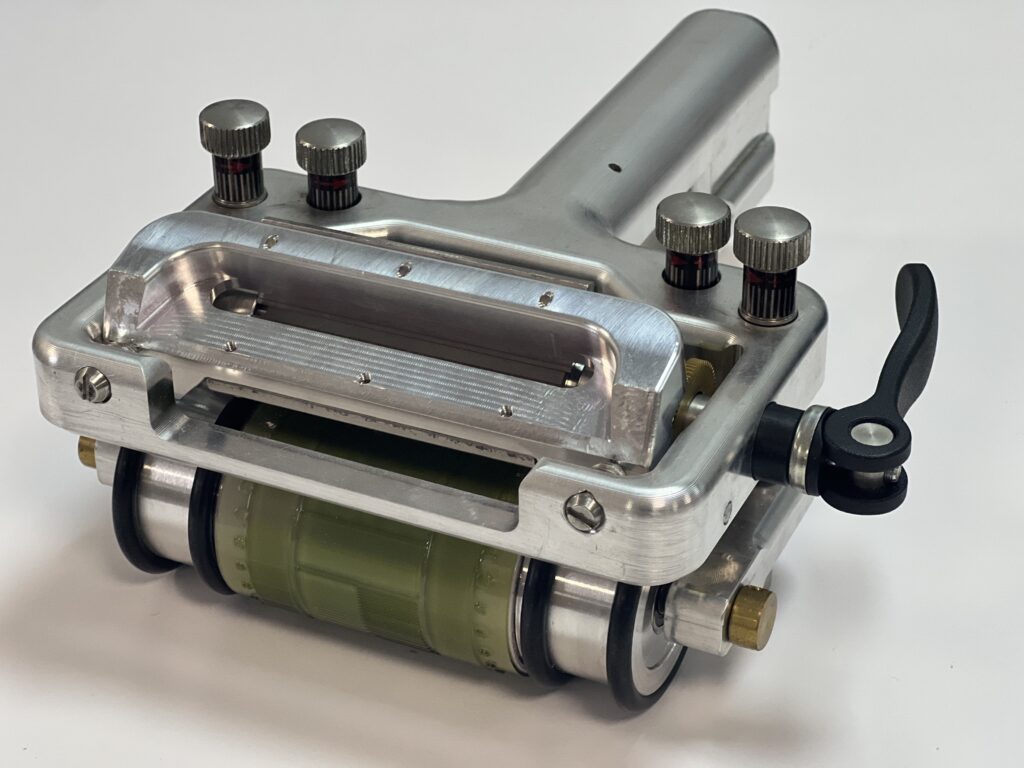

Meet the Evolution Series ES 100, the perfect proofer for flexo. This hand held proofing device utilizes, for example, the same components on your flexographic printing press, including plates, sticky bag and doctor blades. Subsequently, by making a draw down, you will have a truly proof of the ink like on press. Hence, the ES 100 is designed to use all of your 1″ anilox rolls and are easy to exchange.

The ES 100 is easy in use, and also highly effective. This modular build color proof solution can, for example, be adjusted towards your flexo press settings. A simple adjustment of flexo plate and anilox, in similar fashion to your press set-up, will improve the prediction of your color outcome on your press.

Resembles your print press

The ES 100 uses likewise photopolymer plates as you use on your presses. Therefore the used plate material can be processed by yourself. This results in flexibility as well as enables you to customize your plate files, and resolution of plate to your own testing requirements. Furthermore, the patented dot gain technology gives you the ability to measure density and dot gain on your draw down, assuring accurate prediction of the ink performance on press.

Features

- You can use any 1″ anilox

- Snap in dual blade ink metering system

- Toolless quick change anilox

- Designed for any anilox plate and sticky bag thickness

Benefits

- Enables you to mirror anilox on press

- Easy and clean way of doctoring

- Enables using different anilox types

- Enables to mimic flexo plate and sticky bag use on press