Raising the image…… can anything be improved?

UPrint Technologies proudly launches a new screen for tactile printing, 75 Mesh Extra

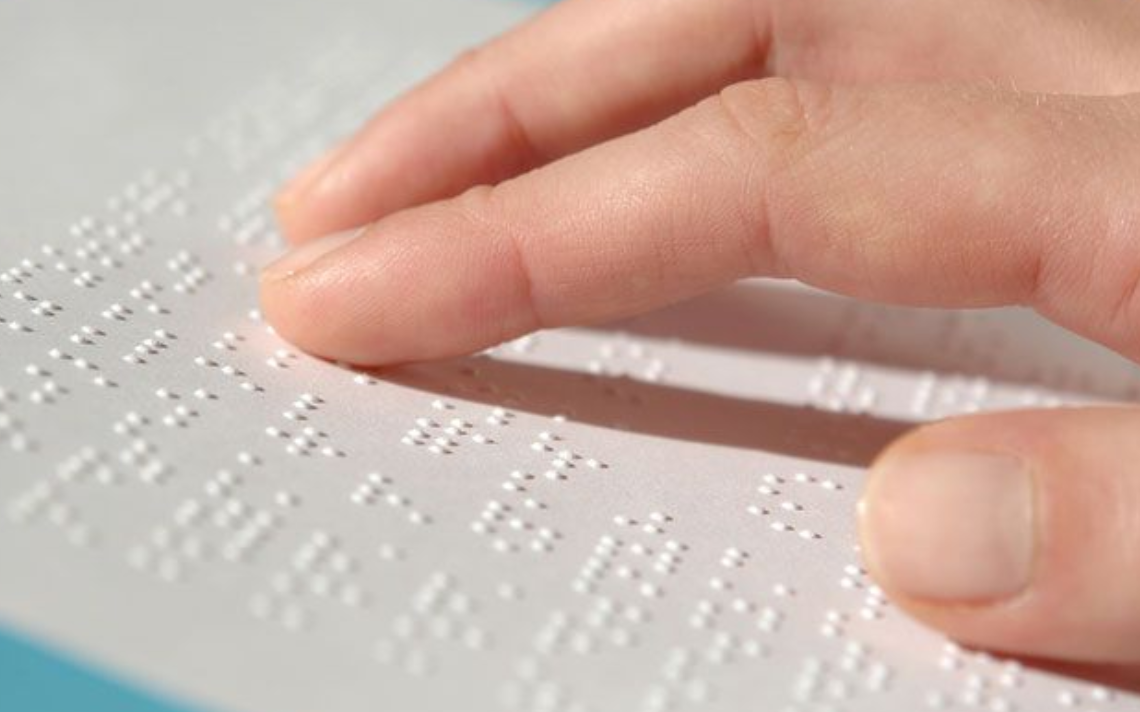

Screen for Braille printing; a well accepted technology in label printing

When it comes to printed Braille, the usual method is to use rotary screen printing as a narrow web combination process. For instance, screen printing is ideal for laying down thick layers of ink or a colorless varnish in a single pass to form the raised dots within precise limits.

But also a labor intense process

The reached Braille printing results with rotary screen exacerbates the labor intense process of applying multiple emulsion layers (up to 40 with a typical target total thickness of 220 – 230 micron) and long machine occupation when you engrave the stencil digital.

But what if we could achieve the same printing results and reduce time to press?

Innovation by UPrint Technologies, because we are committed to label printing

In brief UPrint Technologies is proud to announce the launch of innovation in screen Braille printing with:

75 Mesh Extra

This rotary screen provides equal print quality compared to regular 75 Mesh. Due to higher screen thickness (200 micron instead of 150 micron), you need significant less emulsion to reach the same target thickness of 220 – 230 micron. In fact, you can reach this required thickness with only 10 – 15 emulsion layers*).

Efficiency in both pre press as well as quick time to press

For instance, the reduction of emulsion layers will shorten the screen making process. Combined with faster digital imaging of the screen, you furthermore improve time to press.

This is another example of UPrint Technologies’ commitment to the label printing industry.

UPrint Technologies, LLC

*) each emulsion layer assumed to be 2 micron, following the lacquer viscosity and room temperature

Technical Specifications of both 75 Mesh/40% Compared

| Specification | Mesh | Thickness | Open Area % | Hole Diameter | Ink Deposit Thickness | Maximum Ink Particle Size |

| 75 – 150 – 40% | 75 | 150 | 40% | 214 | 60 | 71 |

| 75 – 200 – 40% | 75 | 200 | 40% | 214 | 80 | 71 |