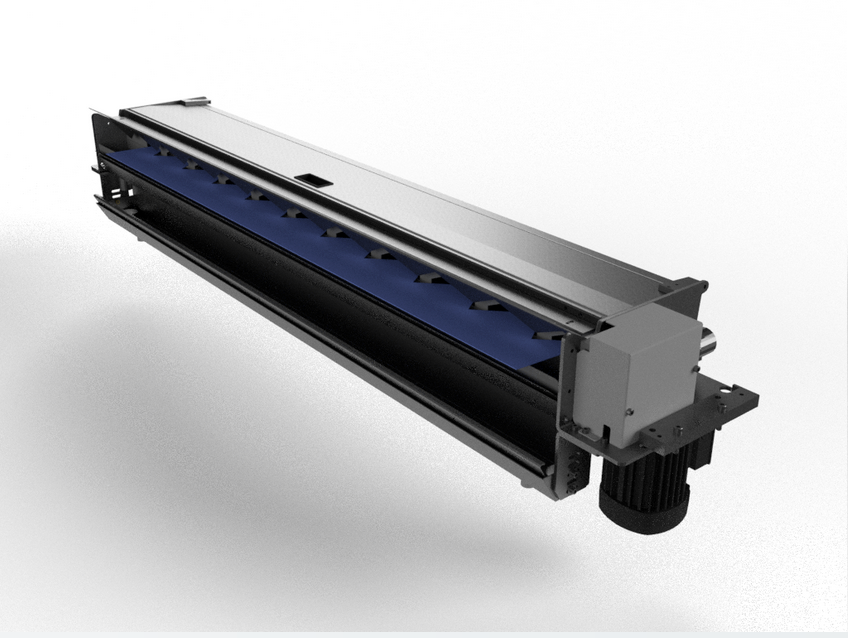

Weko ESC

ESPECIALLY UNIFORM PRECISE POWDER SPRAYING

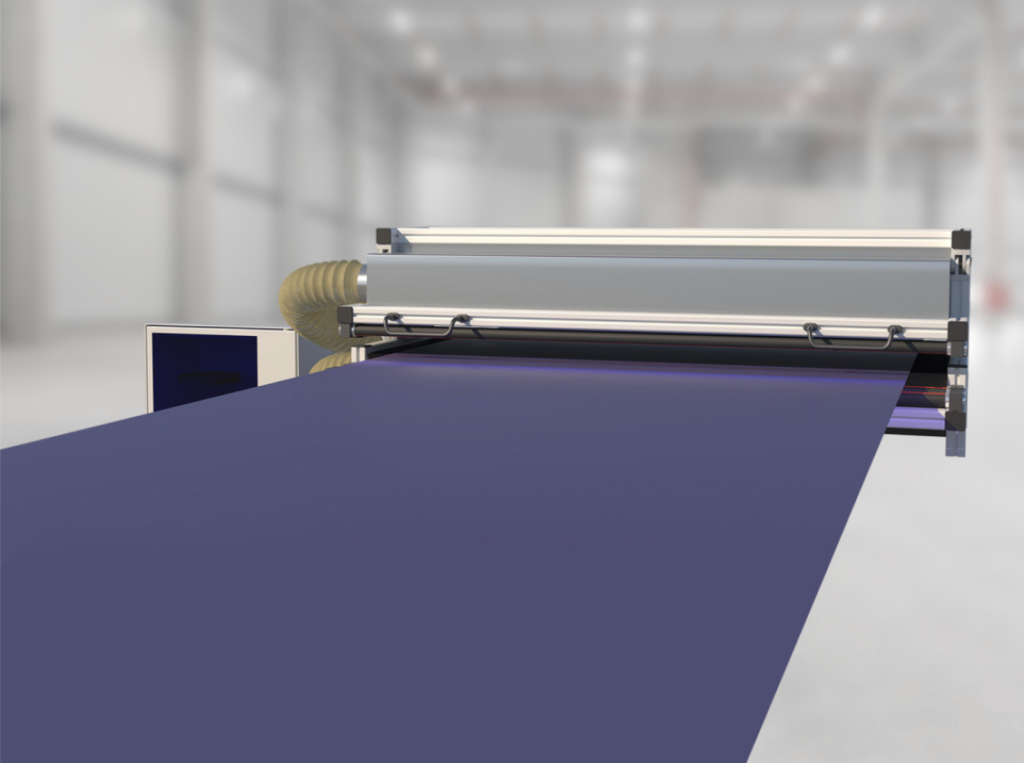

The WEKO Powder Application system is engineered especially for the high requirements on advanced machines in the gravure and flexo printing, plastic film production and specialty applications. Specifically when a very uniform and precise layer of powder is needed and high production speeds are the norm.

The principle explained in brief

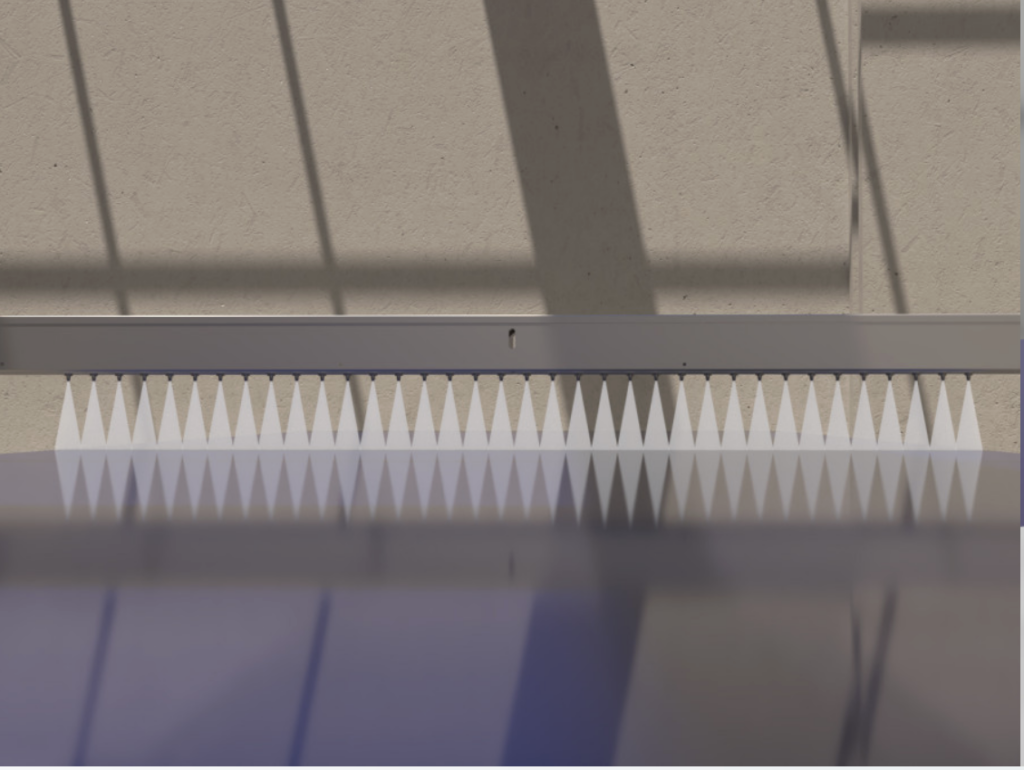

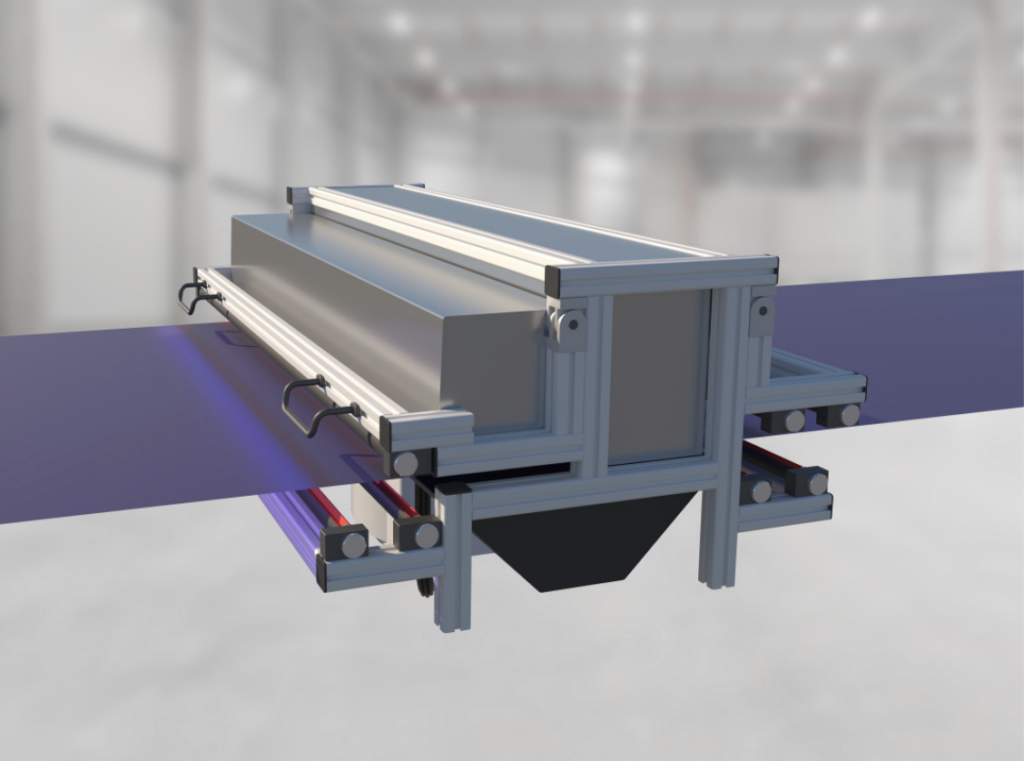

The WEKO ESC is a modular system, which consists of a powder application and an electrostatic unit. First, the web is guided through an ionizing unit. This is needed for the purpose to allow uniform spraying, regardless of the climate or electrical charges. Thereafter follows powder spraying inside the encapsulated spraying chamber. A powder extraction system keeps the air clean. When the web exits the equipment, it is once more discharged through ionizing rods.

A reliable and flexible powder application solution

An advanced powder metering system ensures the uniform precise powder spraying. For instance, even tiny quantity changes can be sprayed exactly and repeatable. What’s more, format setting and adjustment of the powder quantity to the speed or the width of the web is done semi-automatically. Additionally, the type of powder can be quickly changed through the Variobox. The WEKO ESC is available for different powder volumes and to a maximum of 4 meters web width.

Your Benefits

- defined application quantity with large dynamic range, reproducible at any time

- uniform powder application due to ionization system

- choice of three models (4 m maximum width, up to 48 nozzles)

- Variobox® mainly as standard

- integrated powder extraction system (PAS)

- PMS metering system with pre-select function

- hardly any cleaning effort due to minimal powder dusting

- semi-automatic format and speed adjustment

- powder consumption greatly reduced

- easy to operate and maintain

- long service life

WEKO | Flow and SIGMA Liquid Application System

NON-CONTACT LIQUID APPLICATION SYSTEM

WEKO Flow and Sigma Liquid

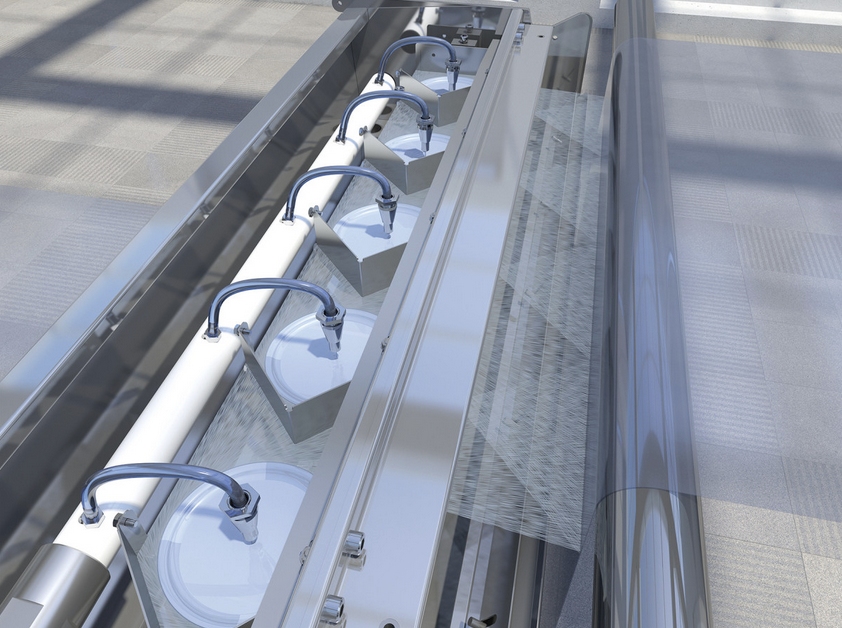

The WEKO | Flow and WEKO | Sigma is a non-contact liquid application system with a unique spray window. For instance, a wide variety of liquids (water and oil based) can be applied with the highest precision and reproducibility to enhance surface functionality on different materials. The rotors are individually supplied with the desired amount of liquid via specially designed throttles and the frequency-controlled pump.

The WEKO | Flow and WEKO | Sigma non-contact liquid application technology in brief

The WEKO | Flow liquid supply unit transfers the chosen liquid to the WEKO | Sigma rotor carrier. The flow unit controls the desired amount of liquid. The rapid spinning rotor discs create a pre-defined jet stream of micro droplets sprayed onto the surface. These droplets form therefore a consistent and evenly film onto the surface. What’s more, the application volume adjusts to the speed of the web. Additionally, non-sprayed liquid will return to the storage tank of the machine.

Typical Applications

The WEKO | Flow and WEKO | Sigma finds its usage in a wide variety of industries. For example, in the Paper Printing Industry to re-moisten paper, release liners for self-adhesive labels, packaging liners, abrasive papers, coating applications and many more.

Your Benefits

- Contactless and precise minimum application

- Single-sided, double-sided or different applications per side

- Fully variable format settings (option)

- Automatic speed adjustment

- Shutter system for fast start/stop/standby function

- High production speeds up to 2000 m/min.

- Working widths from 292 mm up to 7500 mm

- Low maintenance and spare parts requirements

How to start?

UPrint Technologies has a very advanced team, that will advise you about the possibilities of the WEKO technology. With your call, we will get you started and experience how the WEKO technology will improve the digital printing results. We also offer the option to run test trials or provide equipment loaners for dedicated performance test.