Choosing the right squeegee

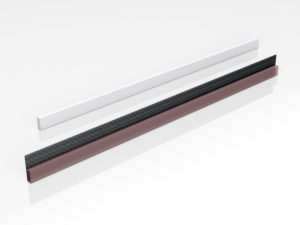

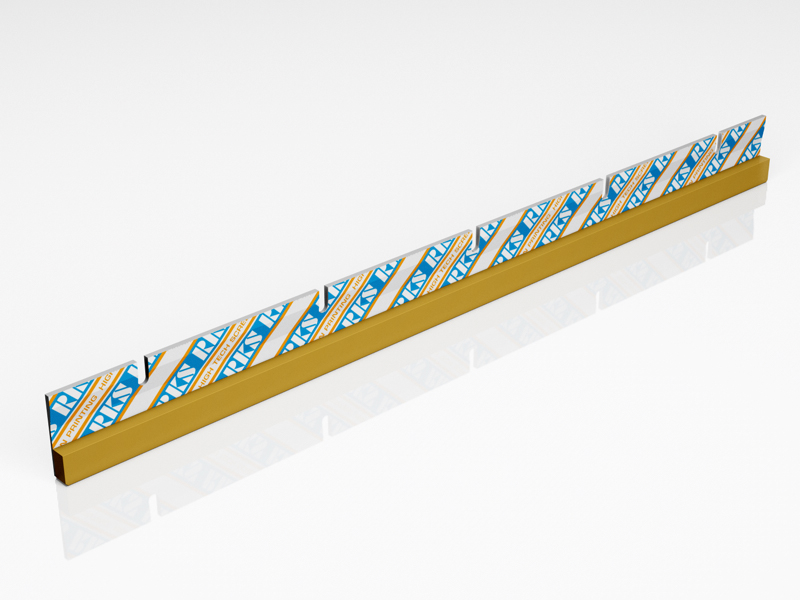

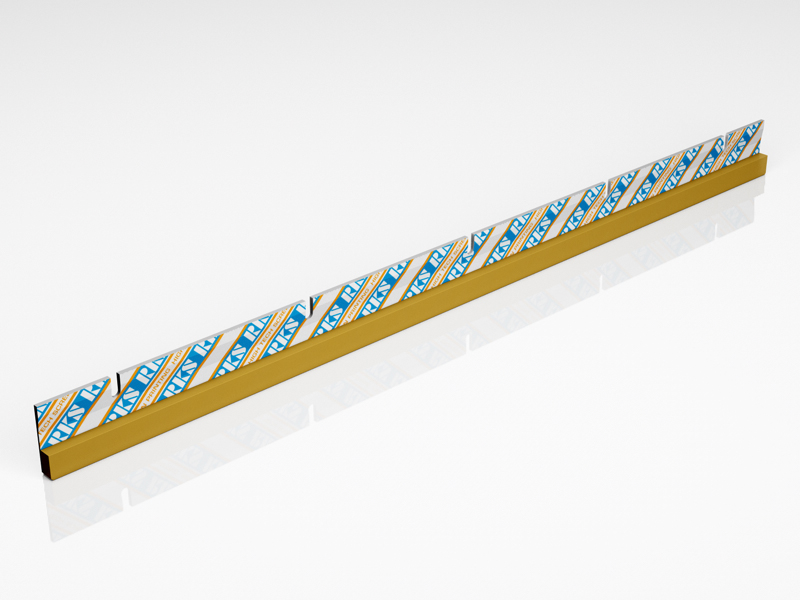

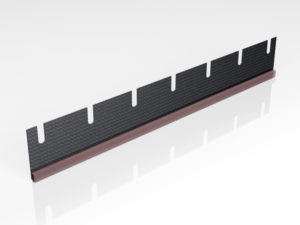

RKS Rotary Squeegee Type RS WP (for Gallus)

DO NOT SETTLE FOR LESS

RKS ROTARY SQUEEGEE TYPE RS WP (for Gallus)

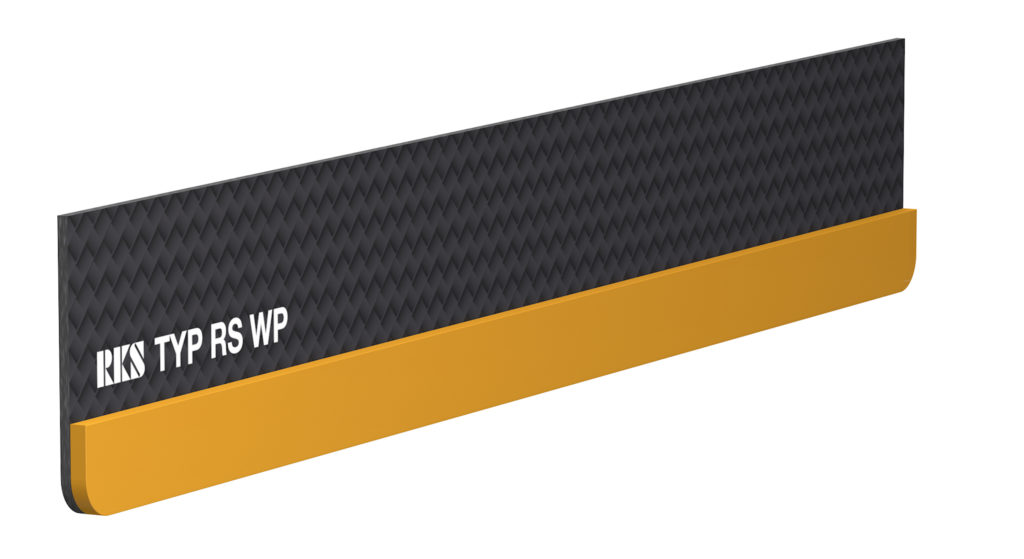

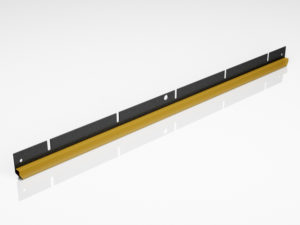

The RKS rotary squeegee type RS WP is a highly flexible squeegee blade, additionally sturdy enough to meet required printing parameters. Thus, the required parameters such as squeegee angle, parallel and pressure can still be set without taking any form or memory during, or after use of the squeegee.

While it is printing results that matters

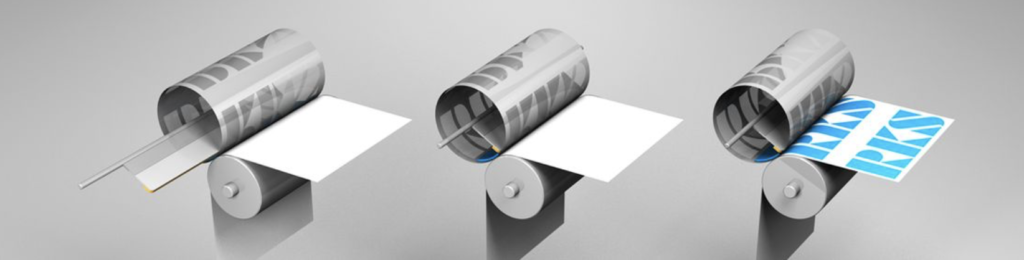

As an illustration, the design of a RKS RS WP squeegee will improve your printing efficiency. In contrast to the commonly used standard stainless steel blade, the RKS RS WP will enable a substantial higher printing speed (up to 15% increase), with no compromise to the desired printing quality.

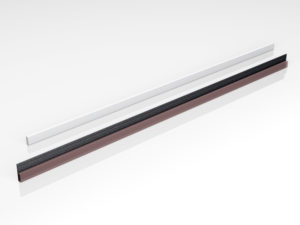

Type RS WP: A squeegee that last long

Additionally, the insoluble bond between the career and the elastic print edge is a unique innovation by RKS. Consequently, the squeegee provides you a longer lifetime. And what’s more, the design of the squeegee tip is less invasive to the screen, therefore you can expect an increased life expectancy of your screen.

Most importantly is to standardize your Rotary Screen Printing Process

Specifically, the advanced RKS RS WP rotary screen blades support standardization of Rotary Screen printing. This is true, nonetheless the speed or design of your print job.

As a result of the research and development of RKS, and working closely with the company Gallus, Fred Ruesch AG, we created a squeegee that complements the required specific parameters settings. Therefore, we will meet the quality demands of high end printing requirements for the Gallus Screen Printing Heads.

A squeegee can only be defined as RKS RS WP rotary blade when it is made from the very best glass fibre support. Additionally the usage of irremovable, and highly resistant Vulkolan ® for this product type.

In conclusion, the RKS RS WP squeegee gives you improved printing results, reduces your print down time and are more economical in use.

Finally, let us help you to find the right specifications for your Gallus Label Press

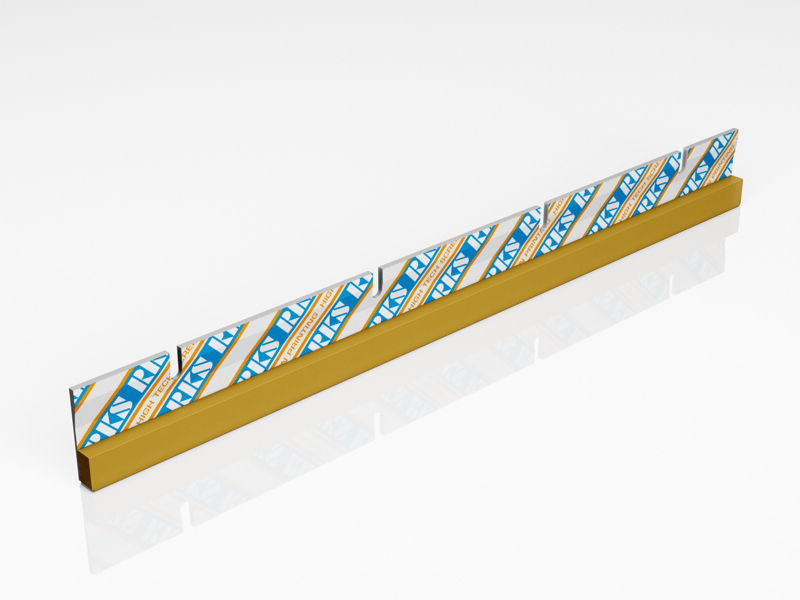

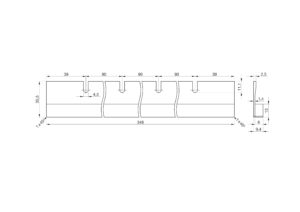

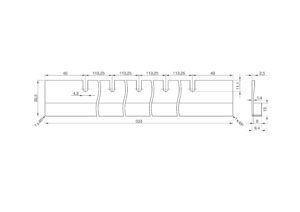

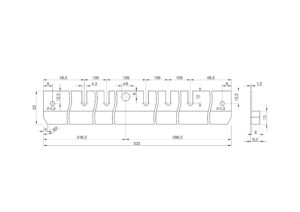

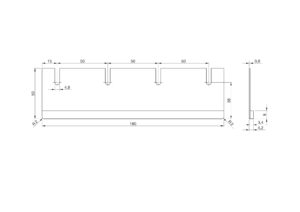

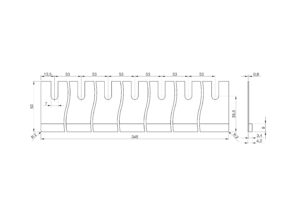

RS WP TYPE ECS

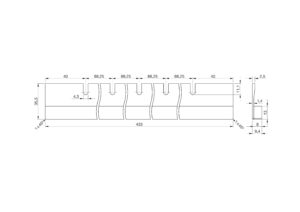

RS WP TYPE GALLUS EM

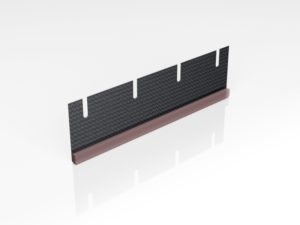

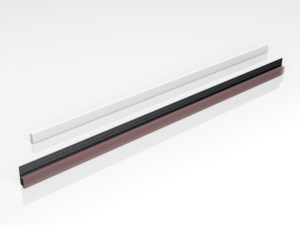

RKS SYSTEM SQUEEGEE TYPE EM (S)

CARBON S TYPE GALLUS EM (S)

RS WP TYPE GALLUS R

RS WP TYPE GALLUS RCS

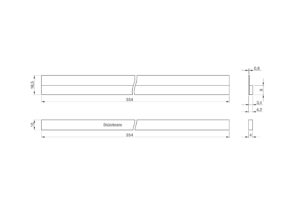

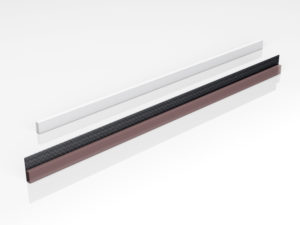

- besides highly flexible, also stabilized double component blade

- both print edge (VU) insolubly bonded to carrier, as well as excellent surface characteristics

- defined plain parallel surface, as well as ground print side, and edge

- RKS RS blades are immediately ready to print

- important higher printing speed (up to 15%)

- excellent quality of high deposit, solid, as well as fine print

- significantly longer lifetime of both screen, and squeegee (in contrast to stainless steel)

- outstanding material qualities, and stability

- increased efficiency as well as print quality

- cost savings through both lower blade consumption as well as reduced screen damage

- reduction of maintenance

| High ink deposit (f.e. Braile) | (T) = 3.0 mm / (A) = 55 Shore (DIN A) |

| Conventional Print (Solid) | (T) = 2.0 mm / (A) = 65 Shore (DIN A) |

| Fine line and text | (T) = 1.5 mm / (A) = 75 Shore (DIN A) |