Advanced anilox deep cleaning

MAKE YOUR PRINTING BETTER

Advanced anilox cleaning with Deepwave

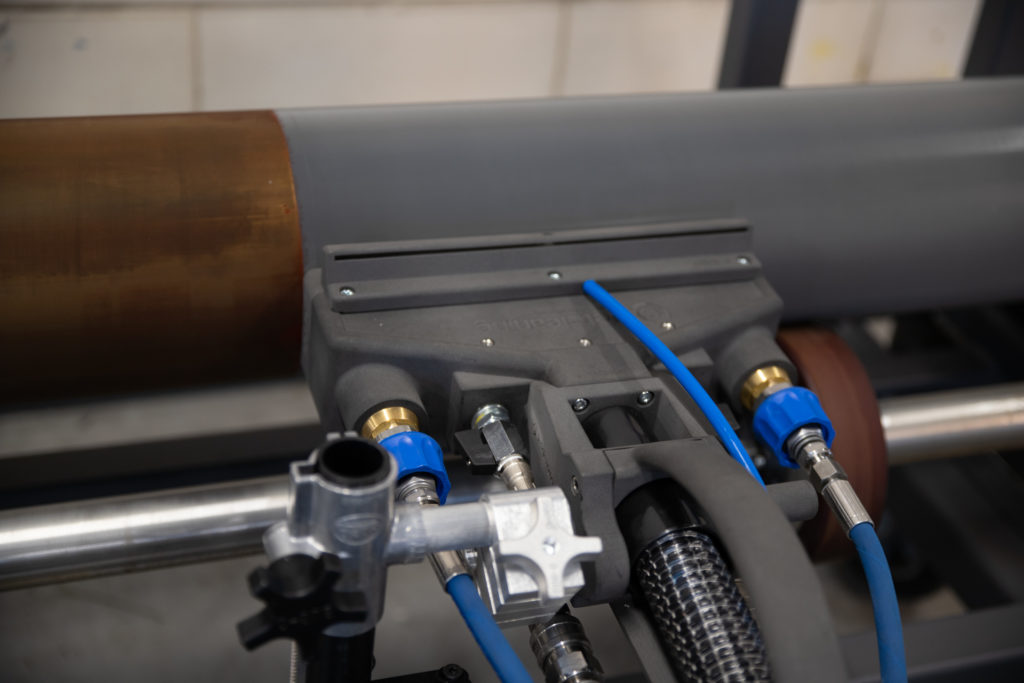

A clean anilox will print better. In fact, with this principle in mind, Clean Solutions Group has engineered a deep cleaning technology. Therefore, meet the next generation of advanced anilox cleaning with Deepwave, a highly efficient and effective anilox deep cleaning device. The Deepwave is not only effective in cleaning, but also maintains the integrity of the cells and dams. As a result, the Deepwave can bring the cell volume back to 95%

When you meet the latest development in anilox deep cleaning: The Deepwave, powered by Clean Solutions Group. The Deepwave is besides fully automated also a non contact anilox cleaning tool. In addition, this concept can achieve a cell volume up to 95%. Therefore, the Deepwave is a game changer in anilox deep cleaning. It also means your printing staff will achieve the color requirements faster.

At the same time, the combined powerful spray and suction head will support you to be in compliance with the strictest company safety policies. Because there is no vaporization of water, cleanser or other material during deep cleaning. Equally important to the cleaning results, this design contributes to realizing a clean and safe pre-press working environment.

This best in class anilox deep cleaning solution can be used both in-line as well as off-line.

Flexoclean Deepwave for anilox cleaning

| Cleaner Volume | 20 liter | Operational Temperature | 25o C |

| Tank Volume | 60 liter | Water Supply | 3/4″ |

| Pressure | 83 Bar | Total weight | 50 kg |

| Suction Unit | 2 x 1200 W | Weight guiding mount | 20 kg |

| Total Output | 4 kW | Minimum Cleaning Height | 70 cm |

| Voltage/Amperage | 380 / 16 V/A | Maximum Cleaning Height | 250 cm |

UPrint Technologies Anilox Services

MAKE YOUR PRINTING BETTER

A Clean Anilox. Better Printing Results.

The heart of flexo printing is the anilox. Therefore, a clean anilox will contribute to better printing results. For that reason, our services are aimed to achieve such a cubic volume of your anilox, as if the anilox is brand new. Thus, the returned and clean anilox will bring better printing results. Additionally, you can benefit from Clean Solutions Groups’ experience through UPrint Technologies improving anilox performance service team. We provide the following services:

- cubic volume measurement

- overview of the state of each printing tool through and clear reporting per anilox roll

- help when encountering printing problems

- training your staff to implement a good cleaning protocol

- deep cleaning service of your anilox rollers through a revolutionary contact free effective cleaning of the anilox

- install dosing system to dilute cleaners with water

- automate your cleaning process

UPrint Technologies Anilox Cleaning Services

The first step of our service is analyzing your anilox base. We perform this analysis by a 3-D microscopic camera. Next, we deep clean your anilox. After this deep cleaning we will analyze the cleaned anilox and provide you a detailed report about the status of your anilox. Finally, we will recommend a cleaning strategy. This cleaning cycle can repeat once or twice a year, depending on the usage of the anilox.

UPrint Technologies maintains local inventory of your anilox cleaning agents

UPrint Technologies keeps your tailor-made Clean Solutions Group cleaners on inventory to ensure short and efficient delivery lead times. As a result, leading anilox manufacturers recommend UPrint Technologies anilox cleaning services.