Pre-press essentials for screens

THERE IS A WAY TO DO IT BETTER

A market leader in pre-press essentials for screens

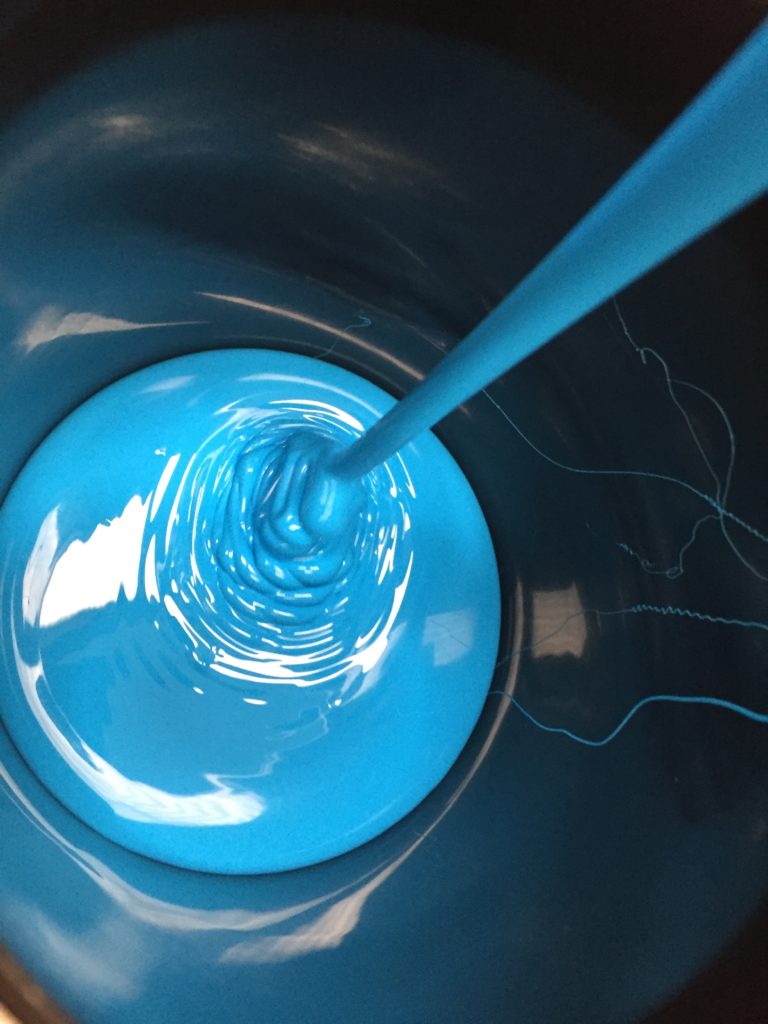

Five decades of dedication to the screen printing technology, as an illustration, features this family owned company at its best. At the same time, AMEX Manoukian is dynamic and also customer requirements focused. This is realized, for instance, through the passion for improving the efficiency and quality of the screen printing technology. Therefore, today AMEX has grown into a market leader position in the pre-press essentials for rotary screen market.

Engaged with customers

Consequently, the market demand engaged customer team of AMEX deploys its decades of experience to find new solutions. But also to keep pace with rapid changing environmental and what’s more the quality requirements. Therefore, this approach will provide innovative products for better printing performance. And so, AMEX offers a complete program of pre-press essentials for making and reclaiming rotary textile as well as label screens.

And developing innovative products

Surely, the core of all AMEX innovation is their sophisticated aboratory. AMEX uses, to illustrate, advanced development technology and high quality raw materials. At the same time, AMEX is respectful for the environment. That is to say, AMEX has developed a portfolio of innovative products. Each solution contributes to improved printing as well as profitability.

As a result highly efficient Pre-press essentials

To conclude, UPrint Technologies offers a complete rotary screen processing portfolio. As a result of the unique formulation of the pre-press essentials, you will achieve high efficiency. But also better printing quality. The next generation photo-emulsion, for example, requires less layers and provides better resistance against ink and as well crisp and sharp details of the printed matter. This solution, for that matter, can save up to 40% in material usage, but also in labor.

Find you application

| Product Name | Application |

| AMEX SCREEN SOL ROTO BLU | Photo-emulsion for the purpose of film, wax, inkjet laser technology |

| AMEX SCREEN SOL ROTO BLU PLUS | Photo-emulsion for the purpose of film, wax, inkjet laser, CTS technology |

| Product Name | Application |

| AMEX SCREEN SOL QS VIOLA | Photo-emulsion for laser exposing (CTS), laser engraving (Co2) technology as well as UV-exposing with film |

| AMEX SCREEN SOL ROTO LASER | Photo-emulsion for the purpose of laser engraving (CTS) technology |

| AMEX SCREEN-CHEM FILLER | One component retouching laquer for the purpose of filling small pin holes |

| AMEX SCREEN-CHEM STRIP | Photo-emulsion remover for the purpose of screen reclaiming |

| AMEX SCREEN-CHEM GHOST | One component ghost image remover for the purpose of screen reclaiming |

| AMEX SCREEN-CHEM DEGREASER | Eco-friendly concentrated degreaser for the purpose to clean the screen before adding the photo-emulsion |

| AMEX SCREEN-CHEM BOND AR | Two components adhesive for the purpose of mounting aluminum end rings |

Innovative Doctor Blades

MOVING FORWARD, TOGETHER

Innovative Doctor Blades by PrimeBlade Sweden

Increase of printing speeds, more colors as well as demand of finer details are today’s challenges in flexographic and gravureprinting. Doctor blades, for example, are used in the most sensitive area of the printing process. Thus there is where the end result is determined. Innovative Doctor Blades by PrimeBlade is how we define solutions for better printing.

We want to make it easier

It is the back bone of PrimeBlade Sweden to make the printing process easier. To create a worry-free print production, with high uptime, reduction of waste as well as keeping production teams happy. That journey starts with finding the right doctor blade for your jobs. Together, we will go over your press operation set-up, length of job, anilox, and also specific inks used. After all, it is necessary to consider the application, i.e. the environment that the material will experience. For that purpose, we have different solutions for any application, in flexo-, gravure, as well as offset printing.

INNOVATIVE PRODUCTS. BETTER PRINTING

A highly innovative technology in doctor blades: Nano. Following a precision technology treatment of the highest quality steel, with the objective to reduce the wear, combined with an increase of the lifetime of the doctor blade and anilox. This special treatment also reduces the environmental impact, which is the objective of many brand owners. Therefore, when choosing PrimeBlade doctor blades, you also choose for a circular solution.

Innovation is the key to support the printing process. The state of the art, world-class 900 Nano series products will improve the printing quality. This series is a unique range of doctor blades with enhanced properties. A special patented treatment, inducing changes in the steel, provides reduced wear and thus longer lifetime, as well as improved surface quality.

Complete program

PrimeBlade Sweden completes the supply program with high quality Prime | Seals.

Choosing a world-class supplier

When choosing PrimeBlade high quality doctor blades, you also choose for reliable and the best in class support, such as education, consultation and technical support.