Choosing the right squeegee

THERE IS NO WRONG TIME TO MAKE THE RIGHT DECISION

It is about choosing the right squeegee

When choosing the right squeegee for rotary screen printing, you will achieve higher efficiency and improved printing quality. Therefore, you want to work with a specialist, who understands the squeegee benefits. UPrint Technologies is your squeegee specialist, powered by RKS.

RKS. Established in 1984

When Rudolf August Kuerten established RKS in 1984, he had the ambition to improve the printing quality by providing continuous input to screen printing. Since then, RKS has grown into a world class market leader in squeegee blades to different printing industries.

Better Printing Results

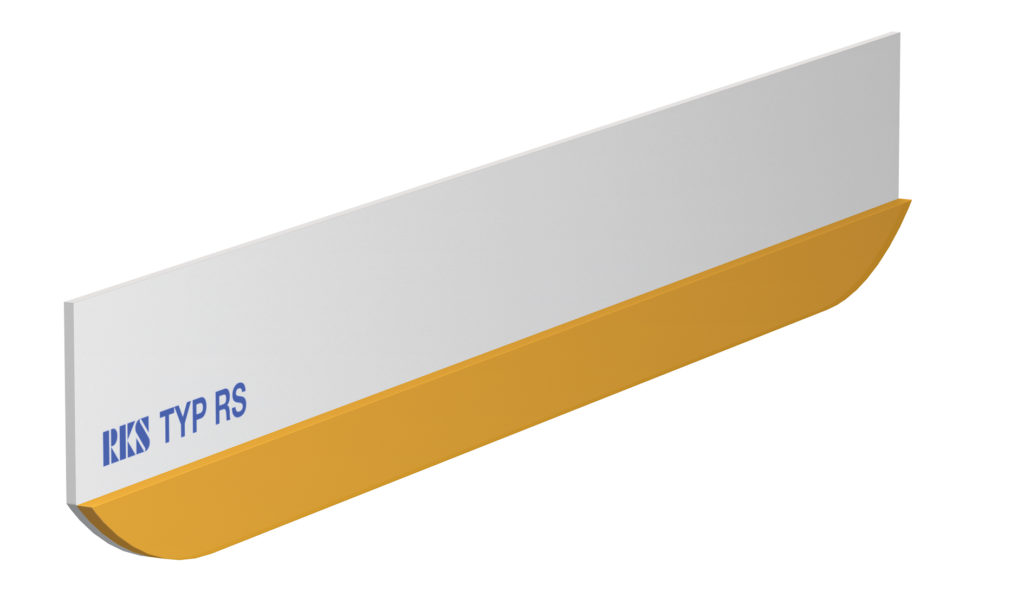

When the right squeegee contributes to a better printing result, it requires the supply of repeatable quality. Thus, RKS is supporting the printing industry by providing high quality products, made up of polyurethane, carbon fibre or glass fibre reinforced plastics.

RKS Philosophy

The philosophy of RKS is to find or develop the right squeegee solution. When working closely with you and a true wish to contribute in improving your rotary screen printing quality. And also by actively participating in several forums that have the objective to exchange knowledge and improve the competitiveness of printing technology, RKS is demonstrating its commitment to various industries.

Top Priority: Quality and Continuous Innovation

The persuasion that the right squeegee contributes to improved printing result is reflected in the company focus and product portfolio. Therefore, this has resulted in a comprehensive product program of systems and stabilized squeegee blades, squeegee grinder, peripherals as well as special application solutions. It is clear, that RKS considers the production of state of the art high quality blades as a science rather than a side activity. That is why RKS considers high quality and innovation as their top priority.

UPrint Technologies, your competent partner

Since the establishment of the company, RKS is a world class market leader in polyurethane and carbon fibre two component blades. UPrint Technologies is the proud distributor of RKS products in North and Central America. The many years of dedicated knowledge and experience makes RKS a competent partner.

Anilox Cleaning Strategy

MAKE YOUR PRINTING BETTER

WELL CLEANED ANILOX ROLLERS….. COST SAVINGS THROUGH BETTER PRINTING

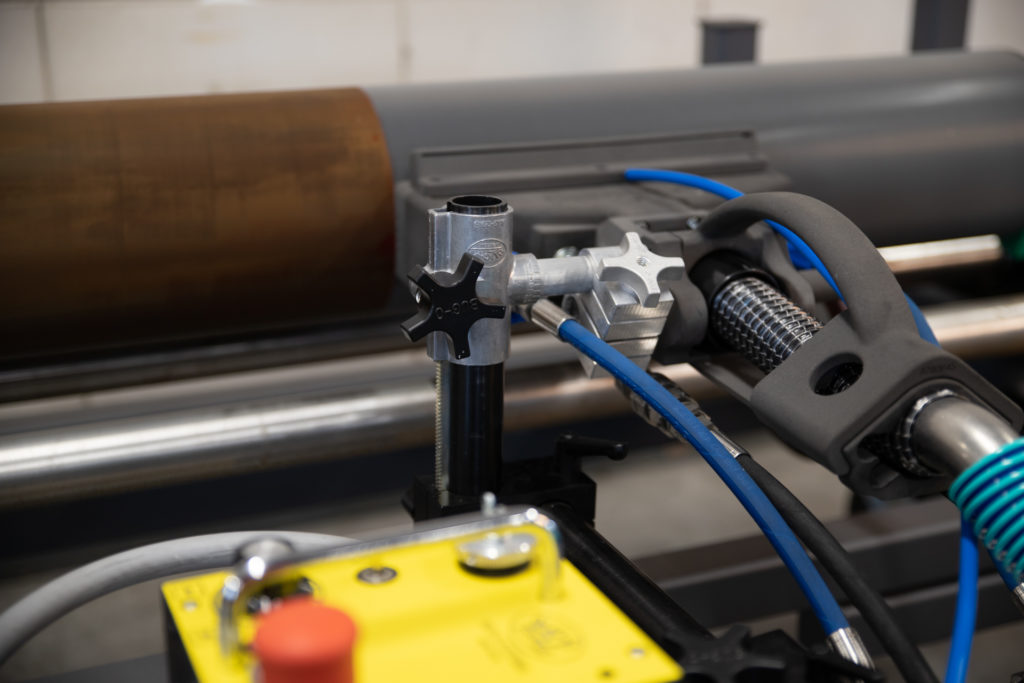

Well cleaned anilox rolls or sleeves are determinative in achieving the required color. Therefore, a balanced anilox cleaning strategy will support your print operation efficiency. UPrint Technologies is here to help you: with dedicated cleaners for daily and weekly cleaning, supplemented by periodic deep cleaning on site by our technicians.

A revolution in periodic anilox deep cleaning: the Clean Solutions Group Deepwave

The Deepwave will fit seamlessly into your anilox cleaning strategy. Besides that this revolutionary contactless deep cleaning device will bring your anilox rollers in the best condition, you will achieve quality printing against low operational costs. In order to help you achieve that goal, UPrint Technologies offers a one of a kind anilox rollers cleaning support plan:

- Analyzing the current condition of your anilox rollers;

- Initial treatment of anilox deep cleaning with Clean Solutions Group Deepwave on site;

- For daily and weekly cleaning you follow our tailor developed Green Solutions Group anilox cleaning plan by using our dedicated Clean Solutions Group cleansers;

- Based upon your usage of anilox rollers, we mutual agree upon a once or twice a year anilox deep cleaning with Clean Solutions Group Deepwave by our anilox cleaning service team;

- Analyzing anilox condition and evaluation.

We are here to help you

UPrint Technologies is there for you to support you in keeping your anilox in optimum condition. We will execute this promise by advising you on implementing a smart cleaning concept. Therefore will our concept contribute highly to more efficient quality printing. For instance through reduction of waste of substrate as well as ink consumption, and by achieving the required color faster. An anilox that transfers the right volume of ink, will also contribute to less machine downtime, as you avoid anilox cleaning during the job. Summarized a well-performing anilox will increase efficiency in printing.