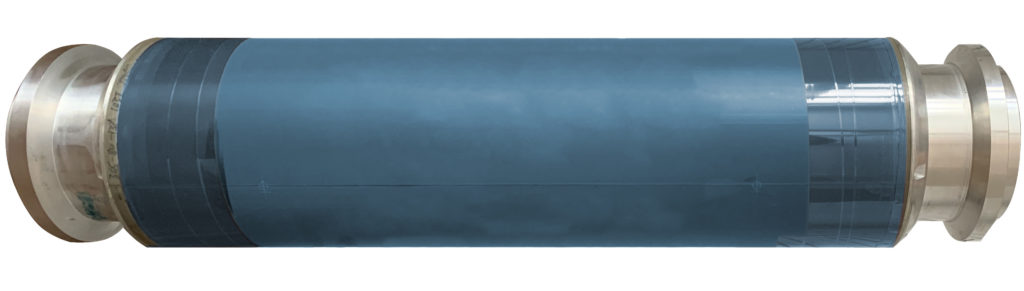

UP Flex Plate

BRING FLEXO PRINTING TO THE NEXT LEVEL

The delicate balance between equipment and consumable

No one else than you knows better that high quality flexo printing requires from you managing the delicate balance between the right equipment and using the right consumables. Therefore, to support you in achieving your high printing quality objectives, UPrint Technologies has developed an aligned solutions concept for better flexo printing:

UP Flex Plate Application

UP-Flex Plate, powered by UPrint Technologies, is an elastomer printing material for that reason developed for use in flexo printing. That is why its typically applications are found in flexible packaging, labels and also in tissue printing.

Additionally combined with the direct laser engraving solution, you will create a standardized flexo plate making process, with guaranteed reproducibility.

More benefits of this plate are that you will realize:

- sharp as well as crisp printed letter type

- both sharp as well as crisp printed ® and © mark

- hence perfect registration

- above all excellent color management

UP-Flex Plate offers longevity in printing, optimum ink transfer as well as high print quality and is solvent resistant. Besides a sheet UP-Flex Plate is also available on a roll. UP-Flex Plate is to this end aligned with direct laser technology, with an unrivaled resolution of 5,080 dpi.

A one of a kind industrialized Flexo Plate making process consisting of only four process steps

Once you choose for UP-Flex Plate combined with direct laser technology you also choose for a standardized four-step flexo printing plate making process:

Step 1.

As a first step the UP-Flex Plate is mounted onto the print sleeve or cylinder. Since you can engrave the plate directly on sleeve or cylinder, precise mounting of the UP-Flex Plate is not needed.

Step 2.

During the next step engraving is done in register when using direct laser solution. The plate is immediately fit to register (no further registration is needed).

Step 3.

Following engraving of the plate, you only need to rinse the plate with water. Because a filter will out coarse particles, residual water is harmless

Step 4.

Finally the plate is ready to print. UP-Flex Plate is reusable, storable and can also be disposed eco-friendly (considered normal household waste).

A competitive edge

Finally you have an alternative to offer your customers a competitive edge in displaying their outstanding state of the art packaging, with the highest print quality at high production efficiency, short time to press and at the lowest price.

For the purpose of cleaning your UP Flex Plate, UPrint recommends using a dedicated FlexoClean Flexo Plate Cleaning cleanser to achieve the best cleaning results without abrasing your plate or sleeve.

Technical Data

| Material | EPDM / Elastomer Black |

| Shore A | 65 Shore A / 80 Shore A |

| Compressibility | 1.14 mm (135 N/cm2 >_ 0.03mm)* |

| Back | 0.007″ Polyester |

| Plate Thickness | 0.045″ – 0.250″ |

| Maximum width of plate | 50″ |

| Maximum length of roll | 9.5 meters |

| Surfaces | Fine Grind |

| Roughness | Ra : 0.9 micron |

*suitable for UV curing inks, solvent-based inks, alcohol-based inks, as well as water-based inks.

LABELMesh Screens for Label Printing

DESIGN IS INTELLIGENCE MADE VISIBLE

Image is everything

In order for brand owners to compete in certain highly competitive markets – wine, beauty, specialty foods – image is everything. And the LABELMesh screens for label printing process provides effects that can bring a label to another level.

Screen printing allows for printing on substrates of any shape, thickness, or size. It also allows for printing front and backside of a clear label to ensure that lettering shines through, and clear labels on dark-colored bottles or tubes are often printed with screen white. Also, a greater thickness of the ink can be applied to the substrate than is possible with other printing techniques, allowing for the creation of effects such as tactile and Braille, glitter, scratch offs and raised text. Also, gold and silver screen inks are often used in lieu of foil.

UPrint Technologies…combining supplies for quality screen printing with low TCO

Providing you the highest added value in screen printing is UPrint Technologies’ vision. Consequently, we strive for superior product quality combined with excellent services and solutions. And so you will benefit from UPrint’s commitment through realizing high-quality LabelMesh rotary screen label printing results at the lowest possible operational costs. That is how we define game-changing in screen printing.

Hence, to support you in realizing your high printing quality objectives, UPrint Technologies has developed an aligned range of solutions for rotary silk screen printing:

Rotary Mesh (Silk) Screen

High Precision End Rings

Robust Gear Wheels (born from bakelite)

End Ring and Gear Wheel

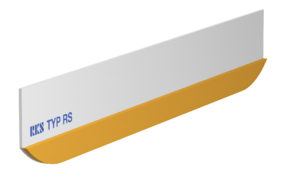

High Precision Squeegees

Auxiliaries for Screen Making and Screen Printing

Long lasting squeegee

The insoluble bond, for instance, between the carrier and the elastic print edge, a unique innovation by RKS, provides you a longer lifetime of the squeegee. What’s more, the design of the squeegee tip is less abrasive to the Mesh, resulting in an increased life expectancy of your screen.

LABELMesh : Rotary (Silk) Screens for Label Printing

A UPrint LABELMesh Rotary Silk Screen for label printing is a Mesh screen electroformed from nickel. A dimensional repeat precision up to 0.01 mm provides you a more economical solution, while keeping excellent print quality. Typical applications are found in label printing to give that high-end look that no other process can deliver, for example when a true “no label” look is desired. Other applications where you can use rotary screen are for example printing tactile (braille), combination varnishes, scent, metallic, high opacity white and color shifting effects.

High Precision End Rings

High precision auxilaries contribute to the perfect label print result. Therefore UPrint Technologies supplies end rings that have a high dimensional precision of TIR of +/- 0.0005″. Because the repeat size of the end ring is laser engraved, the end ring is easy to track.

Robust Gear Wheels

Furthermore, the highly precise gear wheels are made from robust bakelite. This sturdy material will last longer compared to glass fibre, traditionally used to manufacture gear wheels.

A one of a kind industrialized LABELMesh Rotary Screen making process consisting only two steps

Once you choose for UPrint Rotary Silk Screen combined with the AKK DLI Screen imager you also choose for a standardized two-step screen making process:

- image with high resolution AKK DLI Screen Imaging laser solution (emulsion exposing)

- next you wash-out in an AKK screen washer

You now have access to provide your customers a competitive edge, since you offer the highest print quality and high production efficiency, short time to press and that all against the lowest price.

Complete range of screen making as well as screen reclaiming essentials

UPrint Technologies offers a complete range of screen making as well as screen reclaiming essentials, powered by AMEX.

UPrint Technologies helps you in choosing the right Mesh for your print job:

Technical Data

| Mesh (holes/inch) | 300 | 200 | 125 | 75 | ||||||

| Thickness | 80 | 100 | 105 | 200 | 150 | 125 | ||||

| Open Area (%) | 17 | 15 | 13 | 11 | 8 | 25 | 15 | 40 | 40 | 30 |

| Hole Size (microns) | 34 | 33 | 30 | 28 | 24 | 52 | 78 | 214 | 214 | 190 |

| Max. particle size (microns) | 11 | 11 | 10 | 9 | 8 | 17 | 26 | 71 | 71 | 63 |

| Ink Deposit thickness (micros) | 14 | 12 | 10 | 9 | 6 | 17 | 15 | 80 | 60 | 40 |

| Finest line width (mm) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.13 | 0.23 | 0.34 | 0.34 | 0.34 |

| Fine line & text | v | v | v | v | v | |||||

| Halftone & vignette | v | v | v | |||||||

| Coarse line & text | v | v | v | v | v | v | v | |||

| Opaque solid, line, and text | v | v | v | v | v | v | v | v | ||

| Tactile (braile) | v | v | v | |||||||

| Metalics | v | v | v | v | v | |||||