WEKO | DigiCon and WebCon

CONDITIONING THROUGH RE-MOISTENING

WEKO | Digicon

In digital printing, dryer systems are used to dry water-based inkjet inks or to fix toner-based systems. Paper consists of organic fibers whose properties change negatively when exposed to heat.

Conditioning of paper through re-moistening in the High Speed Digital inkjet Printing Industry by WEKO | Digicon or WEKO | Webcon reverses undesirable effects like paper curl, waviness, electrostatic charges and register differences.

Effective and Efficient

Besides supporting excellent printing results, the WEKO technology is also efficient in the exact required sprayed water quantities. Therefore, you are saving valuable resources.

WEKO | Digicon and Silicon Option

Global Player partnering with market leaders of printing presses

Hence, WEKO is a global partner with market leading printing press manufacturers. This is because the WEKO technology sets the industry standard in inline remoistening. Another key point is that with local service and spare part points, we provide the best possible support in servicing and maintaining your spray units.

The WEKO Digicon technology in brief

The WEKO liquid supply unit provides the exact amount of liquid. The integrated pump transports the liquid from a storage tank to the rotor carrier. The rotor disc spindles and forms pre-defined jet stream of micro droplets. These micro droplets spray evenly over the web, and create therefore a uniform liquid film. Unused liquid returns to the liquid storage tanks.

Your Benefits

- Precise, minimal and repeatable application quantities

- Contact-free, clean application (no wrinkling)

- Wide range of applications for all paper grades and ink coatings

- Automatic adaptation to printing speed

- No wear and tear or job-related replacement parts (rollers, sleeves, nozzles)

- High flexibility – single or double-sided application with variable quantities possible

- Highest availability due to automatic cleaning program

- Intuitive, easy operation

- Simple installation without complicated alignment

How to start?

UPrint Technologies has a very advanced team, that will advise you about the possibilities of the WEKO technology. With your call, we will get you started and experience how the WEKO technology will improve the digital printing results. We also offer the option to run test trials or provide equipment loaners for dedicated performance test.

Testing of right amount of remoistening (left no treatment, right various levels of treatment)

WEKO ProTec

FUNCTIONAL TEXTILE FINISHING

WEKO | ProTec

Create a Clean and Safe Working Environment

WEKO | ProTec is an enclosed Application System with extraction capabilities, and thus especially designed for critical chemicals to ensure a clean working environment. Applications range from the Nonwovens Industry to Textiles, Plastic Film and Tissue. Liquid finishes include for instance Antimicrobials, Hydrophobic/Hydrophilic, Softeners, Flame Retardant, Silicones, Oily Lubricants, Resins and many more…

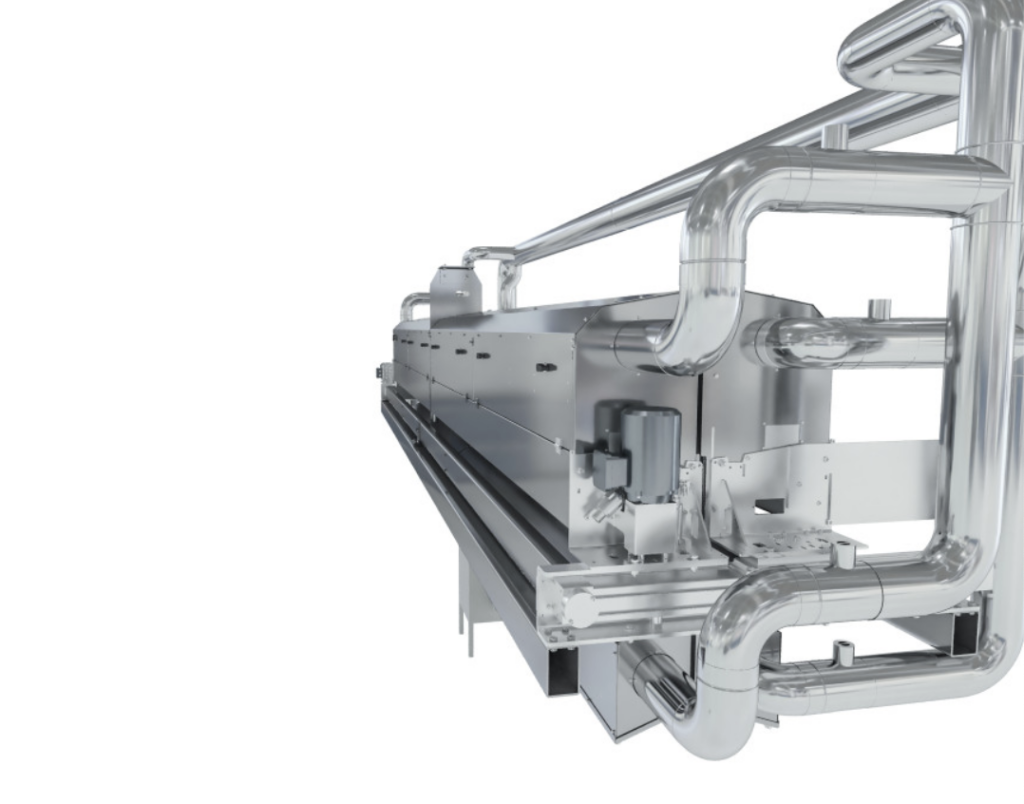

The WEKO | Protec in brief

The fluid is evenly distributed over the web through fast spinning rotor discs by centrifugal forces. Therefore, a uniform film of ultra-fine droplets is created. The WEKO | ProTec consists of two enclosed units, each with a dedicated suction pipe on top and bottom.

This solution has two enclosed elements. Either a rotor carrier unit and a catch unit on the opposite side or with two opposite rotor carrier units working according to the principle of WEKO-Sigma. This allows for high precision, single or double sided web application. The carrier includes an automatic traversing unit to open the system for easy web insertion and high serviceability. The WEKO extraction cabinet has an adjustable extraction volume as well as an exhaust air connection for customer-side piping.

A Safe and Clean Way of Textile Finishing

Thanks to the encapsulated the functional textile finishing is safe. Undoubtedly, this solution protects significantly against escaping of aerosols. Furthermore, the special design creates a clean working environment. The building of the web is easy and fast. A highly efficient extraction unit provides the desired protection, once the unit is closed.

Your Benefits

- Contactless and precise minimum application

- Protection of the production environment and employees

- Single-sided, double-sided or different applications per side

- Fully variable format settings (option)

- Automatic speed adjustment

- Shutter system for fast start/stop/standby function

- High production speeds up to 2000 m/min.

- Working widths from 292 mm up to 7500 mm

- Low maintenance and spare parts requirements

How to start?

UPrint Technologies has a very advanced team, that will advise you about the possibilities of the WEKO technology. With your call, we will get you started and experience how the WEKO technology will improve the digital printing results. We also offer the option to run test trials or provide equipment loaners for dedicated performance test.

Download a Brochure

| Product Brochure WEKO Protec |

| Product Brochure WEKO Protec 2020 |

| Product Brochure WEKO Protec Antimicrobial |